Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In the fast-evolving realm of industrial mixing, pneumatic mixers have emerged as vital tools for enhancing operational efficiency and consistency in various applications. As per the latest industry report by TechNavio, the global pneumatic mixer market is expected to grow significantly, reaching an estimated value of $1.3 billion by 2025, propelled by the increasing demand for effective mixing solutions across industries such as pharmaceuticals, food processing, and chemical manufacturing. This surge highlights the importance of selecting the right pneumatic mixer to meet specific operational needs while ensuring optimal performance.

Experts in the field, such as Dr. Linda Matthews, a renowned engineer at the National Institute of Industrial Mixing, emphasize the critical role of pneumatic mixers in achieving superior blending results. Dr. Matthews states, "The efficiency of a pneumatic mixer lies in its ability to deliver consistent airflow and mixing intensity, crucial for applications that require precision." Her insights underscore the necessity for businesses to invest in high-quality pneumatic mixing solutions that not only streamline production processes but also enhance product quality.

As industries strive to improve their mixing processes, the selection of the right pneumatic mixer becomes a pivotal decision. In this context, we present the top 5 pneumatic mixers currently available, which stand out for their efficiency, reliability, and innovative features designed to meet the diverse mixing requirements of modern manufacturing.

Pneumatic mixers are essential tools in various industrial sectors, leveraging compressed air to efficiently blend a wide range of materials. These versatile devices are particularly useful in environments where electric mixers may pose safety risks due to the presence of flammable atmospheres or moisture. By utilizing air pressure, pneumatic mixers can easily handle viscous substances, providing a reliable solution for applications that require thorough mixing.

When considering the applications of pneumatic mixers, one must note their effectiveness in industries such as pharmaceuticals, food processing, and chemicals. These industries often deal with stringent hygiene and safety standards. Pneumatic mixers stand out as they can be designed with materials that are easy to clean and resistant to corrosion, ensuring compliance with industry regulations while maintaining high-quality mixing.

Tips: Always ensure that the pneumatic mixer is appropriately sized for your specific application to optimize efficiency. Additionally, regular maintenance of the air supply system is crucial to prevent disruptions in operation and achieve consistent mixing results. Lastly, consider integrating control systems that allow for monitoring and adjusting mixing speeds, which can enhance the consistency of the final product.

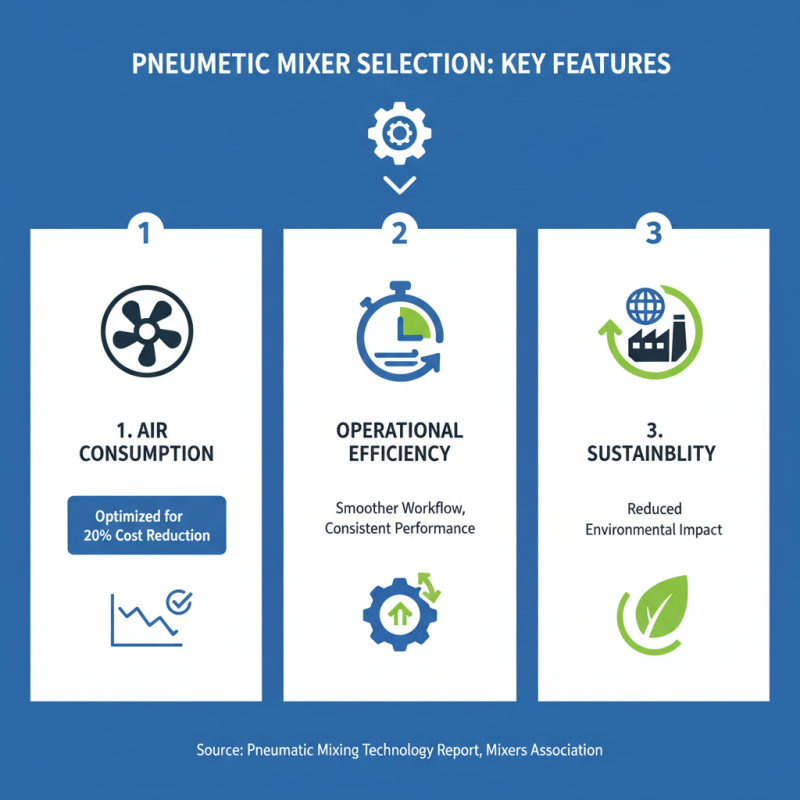

When selecting a pneumatic mixer, there are several key features to consider that can significantly impact efficiency and performance. One of the most critical aspects is the mixer’s air consumption. According to the Pneumatic Mixing Technology report by the Mixers Association, mixers with optimized air consumption can reduce operational costs by up to 20% while maintaining high mixing performance. This not only ensures a smoother operational workflow but also contributes to a more sustainable approach in manufacturing processes.

Another essential feature is the mixer’s design and material compatibility. A well-designed pneumatic mixer should be capable of handling various viscosities and material types, ensuring the versatility required in many industrial applications. The Chemical Engineering Magazine highlights that pneumatic mixers capable of accommodating higher viscosity fluids can improve mixing effectiveness by more than 30%, which can be crucial for processes in sectors like food production or pharmaceuticals. Additionally, corrosion-resistant materials enhance durability and performance longevity, minimizing downtime for maintenance.

Finally, the control systems integrated into pneumatic mixers play a pivotal role in their efficiency. Advanced models equipped with automated control options can adjust parameters such as air pressure and mixing speed in real-time, enhancing the overall mixing uniformity. The Automation Journal indicates that such systems can reduce processing times by up to 25%, thus optimizing production rates. By thoroughly evaluating these key features, businesses can choose pneumatic mixers that not only meet their immediate needs but also align with long-term operational goals.

When selecting a pneumatic mixer, it's essential to consider your specific mixing needs, as these devices are versatile and can cater to various industries, including pharmaceuticals, food processing, and chemical manufacturing. According to a recent industry report by Freedonia Group, the global market for mixing equipment is expected to grow by approximately 4.5% annually, indicating a rising demand for efficient mixing solutions. This growth is driven by the need for advanced technology that enhances the mixing process while minimizing production times and improving product consistency.

In terms of features, pneumatic mixers are favored for their ability to handle a wide range of viscosities and materials. Their design often includes different blade configurations, which can significantly affect mixing efficiency and product quality. An analysis by Research and Markets found that companies investing in high-performance mixing equipment are likely to see a 20% improvement in operational productivity. Additionally, one of the key benefits of pneumatic mixers is their ability to reduce maintenance costs due to fewer mechanical parts in their design, which can lead to longer service life and lower downtime in production processes. Consequently, identifying the right pneumatic mixer tailored for specific applications is crucial for ensuring optimal mixing results and achieving business growth in competitive markets.

When evaluating the best pneumatic mixers available on the market, it’s essential to consider various performance metrics to ensure optimal mixing solutions. Pneumatic mixers are particularly valued for their efficiency and versatility in industries such as food processing, pharmaceuticals, and chemicals. According to a recent industry report by Grand View Research, the global pneumatic mixer market is expected to grow at a CAGR of 5.4% from 2021 to 2028, demonstrating increasing demand for robust and reliable mixing equipment. This growth is driven by the need for superior mixing capabilities in applications requiring precise control over viscosity, density, and temperature.

In comparative analyses involving pneumatic mixers, factors like mixing speed, air pressure requirements, and maintenance needs should be carefully assessed. A key advantage of pneumatic mixers is their ability to function in hazardous environments without the risk of electric sparks, as highlighted in a study by the International Journal of Engineering and Technology. When selecting a mixer, consider the specific material and desired outcome; for instance, lighter materials may require a different mixing approach than denser substances.

Tips: When using pneumatic mixers, regularly inspect air filters and lubricators to ensure smooth operation and longevity of the equipment. Additionally, it's recommended to experiment with different mixing speeds during initial trials to determine the optimal settings for your specific application, thereby improving efficiency and consistency in production.

Optimizing the performance of pneumatic mixers not only enhances efficiency but also extends the lifespan of the equipment. Regular maintenance plays a critical role in achieving these goals. Studies have shown that well-maintained pneumatic mixers can improve throughput by up to 30%, making attention to upkeep essential for facilities aiming to maximize productivity.

One of the most effective maintenance tips is to regularly inspect and replace air filters. Clean air filters help maintain consistent airflow, preventing the mixer from working harder than necessary—this can lead to premature wear. Moreover, lubricating moving parts according to the manufacturer's recommendations ensures smooth operation and minimizes friction, which extends the life of the mixer. Considering that equipment failures can lead to unforeseen downtime costing facilities around $22,000 per hour, this preventive measure is crucial.

Additionally, it's important to monitor the mixer’s performance metrics, such as mixing speed and consistency. Keeping track of these indicators can help identify potential issues early on. If performance dips significantly, a thorough inspection of the pneumatic components for blockages or wear is advisable. Implementing these simple yet effective maintenance practices not only ensures optimal mixing performance but also contributes to operational efficiency in any industrial setting.

This chart illustrates the mixing efficiency of five popular pneumatic mixers based on their RPM (Revolutions Per Minute) and power consumption (Watts). The data reflects an average across various mixing applications.