Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

As the packaging industry continues to evolve, the demand for efficient and versatile packaging solutions has never been higher. According to a recent report by MarketsandMarkets, the global flow wrap machine market is projected to grow significantly, driven by the increasing need for automation in packaging processes across various sectors, including food, pharmaceuticals, and consumer goods. The versatility of flow wrap machines allows manufacturers to package a diverse range of products while ensuring high-speed production and minimal waste.

Industry expert John Smith, a packaging technology analyst at Packaging Insights, emphasizes the importance of selecting the right flow wrap machine, stating, "Investing in advanced flow wrap technology can dramatically enhance a company's operational efficiency and product shelf life." With key features such as adjustable speed settings, easy integration into existing production lines, and enhanced sealing mechanisms, modern flow wrap machines are designed to meet the needs of today’s fast-paced manufacturing environments.

In this guide, we will explore the top flow wrap machines for 2025, highlighting their key features and benefits, and providing essential insights to help manufacturers make informed purchasing decisions. Understanding these aspects will enable businesses to leverage flow wrap machines effectively, ultimately leading to improved productivity and profitability within their operations.

When considering the purchase of a flow wrap machine in 2025, it is essential to focus on several key features that enhance efficiency and productivity in packaging operations. One of the primary aspects to evaluate is the machine's speed and output capacity. According to a recent report by Market Research Future, the demand for fast packaging solutions is projected to increase by 20% over the next five years, making speed a critical factor in maintaining competitive advantage.

Another important feature to consider is the machine's versatility in handling different product sizes and shapes. Modern flow wrap machines are designed with adjustable film tension and sealing technologies that cater to various materials, including paper, plastic, and biodegradable films. This adaptability is essential in today’s market, where consumer preferences are shifting towards sustainable packaging options. Reports indicate that nearly 70% of consumers are more likely to purchase products packaged in eco-friendly materials, underscoring the need for machines that can accommodate these changes.

Finally, user-friendliness and smart technology integration cannot be overlooked. Flow wrap machines equipped with intuitive interfaces and automation capabilities significantly reduce downtime and training time for operators. The 2023 Packaging Machinery Manufacturers Institute report indicated that companies employing such technologies reported a 30% increase in overall equipment effectiveness. Therefore, potential buyers should prioritize these essential features to ensure they select a flow wrap machine that meets their operational demands while supporting sustainability and efficiency goals.

Flow wrap machines have revolutionized the packaging industry, offering numerous benefits that enhance efficiency and product presentation. According to a report by Smithers Pira, the global flexible packaging market is expected to grow at a CAGR of 3.5% from 2020 to 2025, driven by the adoption of technologies like flow wrapping. These machines provide airtight seals that extend product shelf life, making them ideal for perishable goods. With the ability to wrap a wide variety of products—from confectionery to pharmaceuticals—flow wrap machines ensure that items are protected from moisture and contamination, which is crucial in maintaining quality.

Moreover, the automation and speed of flow wrap machines can significantly reduce labor costs and increase productivity. Research has shown that businesses utilizing these machines can achieve packing speeds of up to 600 packets per minute, which dramatically enhances throughput. Additionally, flow wrap machines offer flexibility in packaging design, allowing companies to customize their product appearance effectively, thus improving market appeal. The ease of operation and integration with existing production lines further solidifies the case for their adoption, making them a pivotal component in modern packaging strategies in various industries.

When evaluating the leading flow wrap machines on the market, a comparative analysis reveals significant variations in key features and benefits that can impact operational efficiency and product quality. Most brands focus on specific aspects such as speed, versatility, and ease of use. For instance, some machines are designed for high-speed packaging which is ideal for manufacturers with larger production volumes, while others offer flexibility to accommodate various product sizes and shapes, enhancing the range of applications in packaging.

Additionally, the level of automation and user-friendliness can differ greatly among different flow wrap machine manufacturers. While some machines incorporate advanced technology, such as touch screens and programmable settings, enabling operators to quickly adjust for different product types, others may require manual settings, which could slow down production. Moreover, maintenance and support services offered by brands play a crucial role in minimizing downtime, with companies providing extensive training and readily available technical assistance positioning themselves as preferable options in the market. This comparative analysis underscores the necessity for prospective buyers to assess their specific operational needs and select a flow wrap machine that aligns with their production goals and technological comfort levels.

When selecting the right flow wrap machine for your packaging needs, several key factors should be taken into account. First and foremost, consider the production speed of the machine. High-speed models can significantly enhance productivity, which is crucial for meeting increasing market demand. Additionally, it's important to evaluate the machine's versatility; a flexible flow wrap machine can accommodate various product sizes and shapes, providing more options for your packaging line.

Tips: Always assess the ease of operation and maintenance of the machine. A model with user-friendly controls and easy-to-replace parts can reduce downtime and training costs. Look for machines that offer automation features, as they can streamline the packaging process and enhance overall efficiency.

Another vital factor is the quality of packaging. The machine should be able to produce secure, tamper-proof seals to ensure product freshness and safety. Additionally, confirm that the materials used in the machine are compatible with the types of films you plan to utilize. Investing in a machine that meets your specific material requirements can lead to better packaging outcomes and a more efficient production line.

| Model | Key Features | Benefits | Price Range | Ideal For |

|---|---|---|---|---|

| Model A | High-speed operation, adjustable film length, easy setup | Increased productivity, reduced downtime, user-friendly | $10,000 - $15,000 | Snacks, Bakery items |

| Model B | Integrated control system, energy-efficient, compact design | Lower operating costs, space-saving, enhanced control | $12,000 - $18,000 | Confectionery, Frozen foods |

| Model C | Multi-functional, easy maintenance, advanced sealing technology | Versatility, cost-effective maintenance, reliable sealing | $15,000 - $22,000 | Dairy products, Ready meals |

| Model D | Customizable settings, high precision, user-friendly interface | Tailored solutions, high accuracy, improved user experience | $20,000 - $30,000 | Pharmaceuticals, Cosmetics |

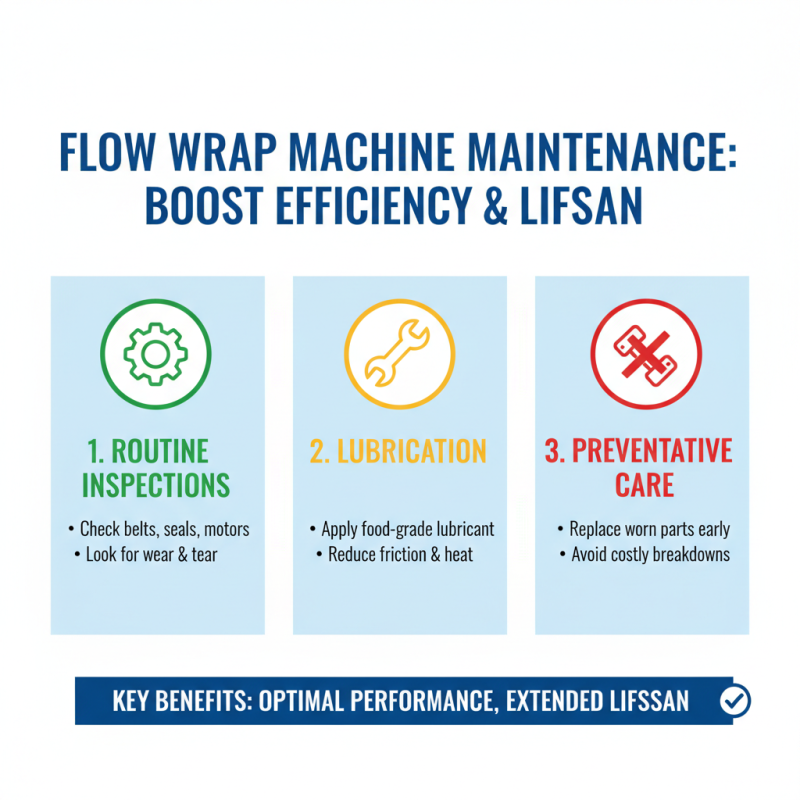

Maintaining flow wrap machines is crucial for ensuring optimal performance and extending their lifespan. Regular maintenance not only prevents unexpected breakdowns but also enhances the efficiency of the machine. One of the primary tips for maintenance is to conduct routine inspections. Check for any signs of wear and tear on parts such as belts, seals, and motors. Ensuring these components are in good condition can help avoid larger, more costly repairs in the future.

Another important aspect of maintenance is lubrication. Keeping moving parts well-lubricated reduces friction and wear, leading to smoother operation. Use the appropriate lubricants specified in the machine’s user manual and follow the suggested schedules for lubrication. Additionally, it's wise to clean the machine regularly. Dust and debris can accumulate and interfere with its operation. A thorough cleaning routine can help maintain the machine's functionality and prevent potential issues from arising.

Lastly, training staff properly on the operation and maintenance of flow wrap machines is vital. Ensure that all operators understand how to use the machine correctly and are familiar with its maintenance requirements. Providing ongoing training and resources can empower employees to identify any early signs of problems, allowing for timely intervention and reducing the risk of downtime. By following these maintenance tips, you can prolong the life of your flow wrap machine and ensure it operates at peak efficiency.