Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In today's competitive manufacturing landscape, the importance of efficiency cannot be overstated. Utilizing a Blow Film Extrusion Machine can significantly enhance production processes. John Smith, an industry expert at Plastic Technologies, states, "Embracing advanced machinery is key to staying relevant." His insights highlight the transformative potential of modern equipment.

Blow Film Extrusion Machines offer various benefits, paving the way for increased productivity. These machines produce films of varying thicknesses, essential for a range of applications. Their versatility can meet diverse market demands. However, implementing such technology also brings challenges and requires careful planning.

Investing in a Blow Film Extrusion Machine means balancing innovation with oversight. Companies must assess their specific needs and market trends. While the benefits are clear, the transition process may reveal areas for improvement. The path forward involves a commitment to adapting in a rapidly changing industry.

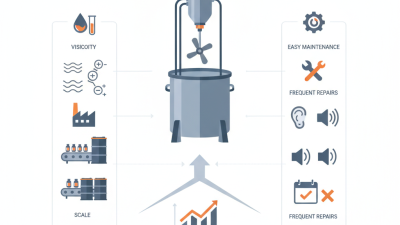

Blow film extrusion machines significantly enhance production efficiency in various industries. They produce high-quality plastic films with precision. This technology allows for continuous production, reducing downtime and increasing output. Operators often report smoother workflows and fewer disruptions. The machines can handle multiple materials, adding versatility to production lines.

Another advantage is the ability to customize film thickness and properties on-the-fly. This leads to less material waste. However, achieving the perfect balance can take time and practice. There can be challenges in controlling temperature and pressure settings. Adjusting these parameters might be necessary as production demands change.

Moreover, maintenance is crucial for optimal performance. Regular checks can prevent unexpected breakdowns. Learning to troubleshoot issues is part of the process. Some operators may struggle with complex systems. Continual training can improve skills and efficiency. With time, businesses often find that investing in this technology pays off.

Blow film extrusion technology is revolutionizing the packaging industry. This method allows businesses to produce high-quality film at lower costs. According to a recent industry report, companies can save up to 30% in material costs by adopting this technology. The process is efficient and environmentally friendly. Reduced waste contributes to cost savings.

Optimizing manufacturing processes can lead to better profit margins. The versatility of blow film extrusion machines allows for various applications. This flexibility can help businesses cater to different markets, maximizing revenue potential. Reports indicate that the demand for blown film products has risen by 15% annually. This growth trend signifies strong market opportunities.

Tips: Consider a thorough cost analysis before investing in new machinery. Check for potential energy savings as they can significantly affect your bottom line. Regular maintenance of your blow film extrusion machine will ensure optimal performance and reduce long-term costs. Keep an eye on industry trends to remain competitive, but don't ignore the unique needs of your business.

Blow film extrusion plays a crucial role in enhancing the quality of materials used in various applications. This process allows for the creation of films that exhibit excellent strength and flexibility. The unique method of stretching the polymer melt helps in achieving a more uniform thickness. Additionally, the cooling process ensures a robust structure that resists tearing and puncturing.

One significant advantage of blow film extrusion is the ability to modify properties during production. By adjusting parameters, manufacturers can produce films with varying barrier characteristics. This adaptability is essential in industries that demand specific material properties. Yet, achieving perfect consistency can be challenging. Inconsistent temperature control may lead to variations in thickness. Manufacturers must remain vigilant to prevent defects.

Furthermore, blow film extrusion can contribute to sustainability efforts. The technology allows for the use of recycled materials, thus reducing waste. However, the quality of recycled polymers can often be unpredictable. This unpredictability may affect the final product's performance. Therefore, it is crucial to conduct thorough testing. Embracing these challenges is essential for continuous improvement in material quality.

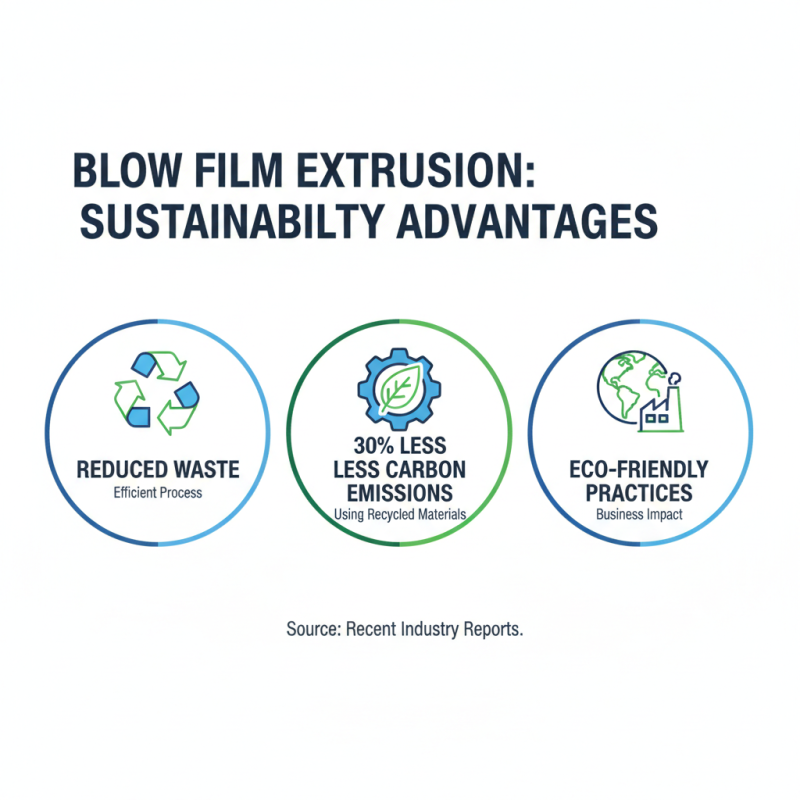

Blow film extrusion is increasingly recognized for its sustainability advantages. This process allows for the efficient creation of plastic films while reducing waste. According to recent industry reports, using recycled materials in blow film extrusion can lower carbon emissions by 30%. This is a significant impact for businesses aiming to adopt eco-friendly practices.

One key benefit is energy efficiency. Blow film extrusion machines can produce films with less energy consumption compared to traditional methods. A professional study indicates that modern machines can save up to 50% on energy costs. Such savings are crucial for small businesses trying to balance expenses with sustainability goals.

Tips for getting started with eco-friendly practices include reviewing your material suppliers. Consider using recycled or biodegradable materials. Investing in advanced machinery may require initial capital, yet the long-term savings are compelling. While the industry evolves, businesses must continuously seek improvement. Stay informed about new innovations to remain competitive and environmentally responsible.

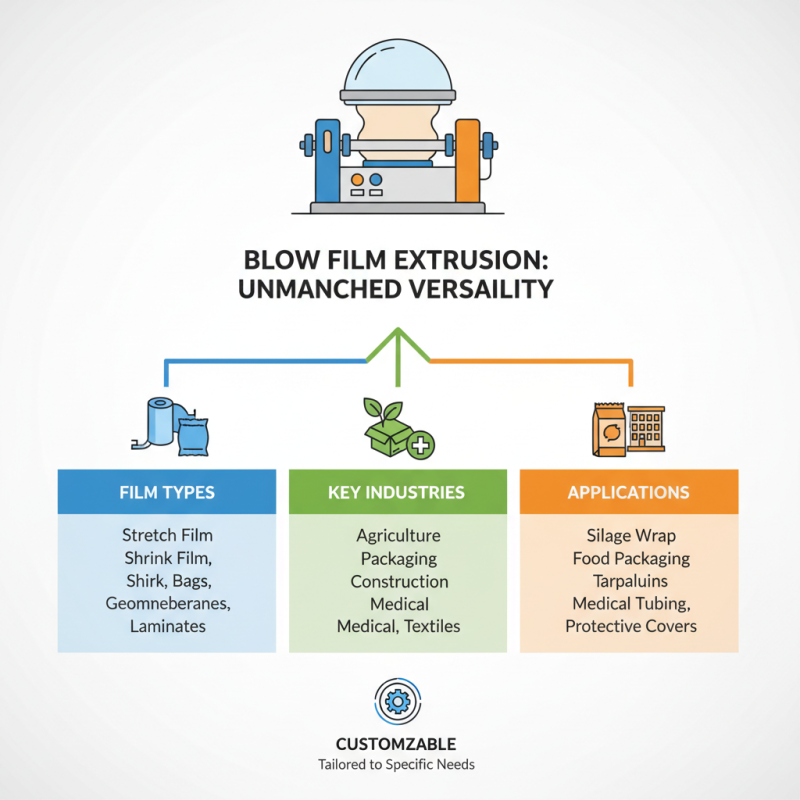

Blow film extrusion machines offer immense versatility. They can produce various film types, catering to different industries. From agriculture to packaging, the applications are vast. Each product can be tailored to specific needs, ensuring effectiveness.

Customization is key. You can adjust thickness, strength, and texture. This way, the film meets exact requirements. Clients often request unique features, such as UV protection or added durability. However, achieving perfection may require experimentation. Sometimes, the prototypes might not meet expectations. It’s a process of trial and error.

Here are some tips for effective customization: Focus on material selection. Choose based on the intended use. Collaborate with your team. Input from different perspectives can enhance the final product. Don't rush the testing phase. Allow sufficient time for adjustments. The more precise the settings, the better the outcome will be.