Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In the ever-evolving landscape of material handling, the choice of equipment can significantly impact operational efficiency and productivity. Among the various solutions available, the Bucket Elevator stands out as a pivotal technology for industries that deal with bulk materials. According to a report by the International Bulk Materials Handling Association, the global bucket elevator market is projected to grow substantially, driven by an increase in demand across sectors such as agriculture, mining, and construction. The report highlights that the right Bucket Elevator can enhance material flow, reduce operational costs, and improve overall system reliability.

Selecting the appropriate Bucket Elevator for your business needs requires careful consideration of various factors such as capacity, material compatibility, and installation space. A well-chosen Bucket Elevator not only optimizes the transport of materials but also minimizes downtime and maintenance costs, which are crucial for maintaining competitive advantage. It is essential to analyze your specific application requirements and industry standards, as these criteria will guide you in making an informed decision that aligns with your operational goals and financial constraints. By understanding industry trends and leveraging expert insights, you can confidently navigate the complexities of selecting the right Bucket Elevator to meet your needs.

Bucket elevators are essential material handling solutions widely used across various industries, including agriculture, mining, and manufacturing. Their primary function is to vertically transport granular or powdered materials, allowing for efficient handling and storage of bulk products. Understanding the specific applications of bucket elevators is crucial when assessing your business needs. For instance, grain handling facilities often utilize these elevators to move harvested crops, while powder processing plants employ them to transfer fine materials.

When selecting a bucket elevator, it's important to consider factors such as the material to be transported, the necessary lift height, and the required throughput. Different types of bucket elevators, like continuous and centrifugal, cater to specific applications. Continuous bucket elevators are suitable for delicate materials as they minimize breakage during transport, whereas centrifugal elevators are designed for faster operations with less concern for the material's integrity. Assessing these variables will help in choosing the right elevator that not only meets current operational needs but also aligns with future growth and production demands.

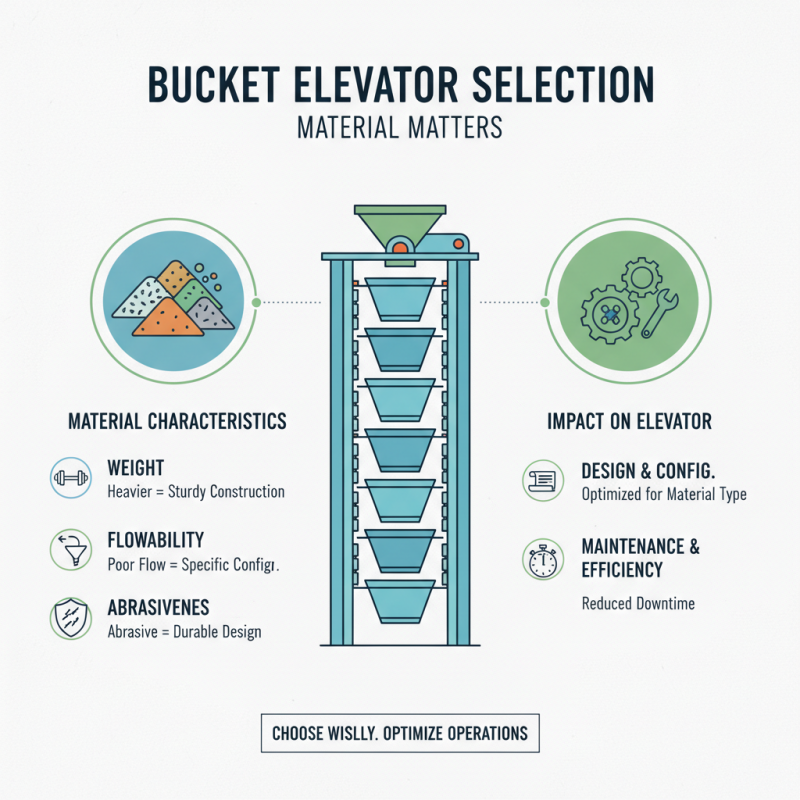

When selecting a bucket elevator for your business needs, several key factors should guide your decision-making process. First, consider the material being handled. Different materials have varied characteristics, such as weight, flowability, and abrasiveness. For instance, bulkier materials may require a sturdier construction to prevent damage, while softer materials may allow for lighter designs. Additionally, understanding the handling properties of your material will influence the configuration and design of the bucket elevator, ensuring it meets operational efficiency and minimizes potential maintenance issues.

Another critical factor is the elevator's capacity and throughput. This involves assessing the volume of material that will be transported and the required speed of movement. Ensure that the bucket elevator can handle the anticipated load while adhering to the required performance standards. It's also important to take into account the elevation height and the layout of your facility, optimizing the elevator’s design to fit within your workspace without compromising on efficiency or accessibility. A well-chosen bucket elevator not only enhances productivity but also contributes to a streamlined operation tailored to your business's specific needs.

When selecting a bucket elevator, understanding the various types available and their suitability for different materials is crucial for optimizing operational efficiency. There are several types of bucket elevators, each designed for specific material handling needs. For instance, belt bucket elevators are ideal for handling bulk materials such as grains and powders, as they provide a gentler lift and minimize product degradation. Chain bucket elevators, on the other hand, are better suited for heavier and more abrasive materials like sand, gravel, or even small metal pieces, given their robust construction and durability.

Another significant type is the continuous bucket elevator, which operates with overlapping buckets and is suitable for fragile materials that require a gentler transport mechanism. These elevators can handle a diverse range of products, including food items such as nuts and grains. Furthermore, modular bucket elevators offer flexibility, as they can be customized in terms of height and capacity, making them suitable for a variety of materials ranging from bulk solids to small granular products. Choosing the right type of bucket elevator based on the specific material’s characteristics is essential to maximize efficiency and reduce maintenance costs in your business operations.

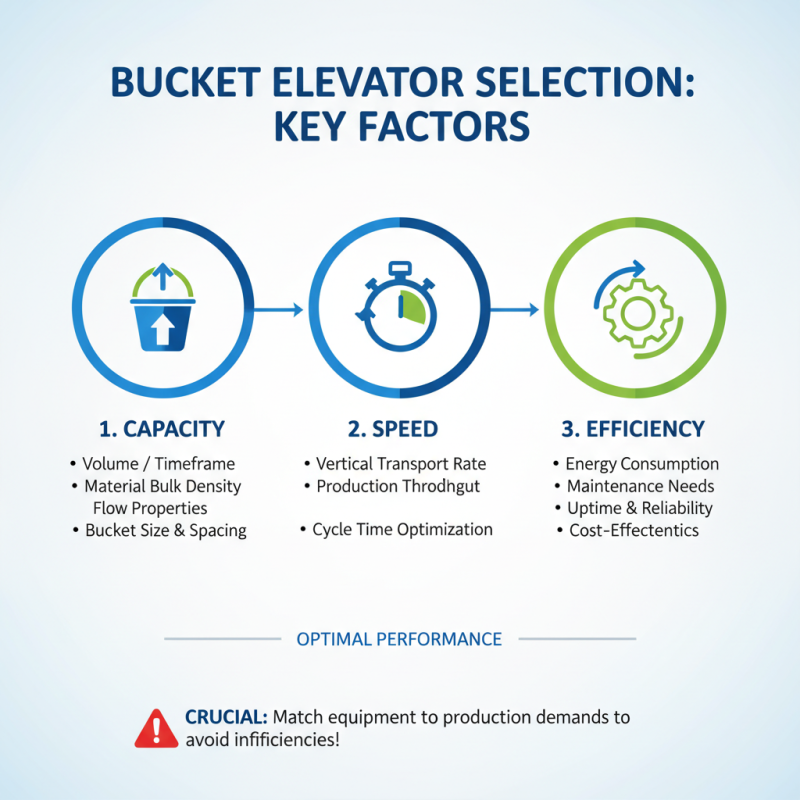

When selecting a bucket elevator for your business, evaluating the capacity, speed, and efficiency requirements is crucial in ensuring optimal performance. Capacity refers to the volume of materials the elevator can handle within a specific timeframe. It's essential to assess the characteristics of the materials being transported, such as bulk density and flow properties, to determine the necessary bucket size and spacing. Businesses must carefully analyze their production demands to avoid under or over-specifying their equipment, as both scenarios can lead to inefficiencies and increased operational costs.

Speed is another significant factor that directly impacts productivity. An ideal bucket elevator should balance speed and the capacity of the load being transported. Rushing materials too quickly can lead to spills and product degradation, while too slow a speed can bottleneck production. It's essential to consider the optimal speed that aligns with the specific material characteristics and operational needs, as well as any potential wear on the equipment. Additionally, evaluating energy efficiency plays a crucial role in long-term operational costs. A well-designed elevator should minimize energy consumption while maximizing output, contributing to a sustainable and cost-effective business model.

In summary, carefully assessing these factors will enable businesses to choose a bucket elevator that meets their specific needs, ensuring reliable operation and contributing to overall productivity and efficiency.

When it comes to choosing the right bucket elevator for your business, maintenance and support play a crucial role in ensuring the longevity of your equipment. Regular maintenance tasks, such as checking for wear and tear, ensuring proper alignment, and cleaning the system, can significantly reduce the risk of unexpected downtime. A well-maintained bucket elevator not only improves operational efficiency but also minimizes the chance of costly repairs or replacements in the future.

Moreover, having a reliable support system in place is essential. This includes access to expert technicians who can provide timely assistance when issues arise and offer guidance on best practices for operation and upkeep. Investing in a comprehensive maintenance plan can help ensure that any potential problems are addressed promptly, thereby extending the life of the elevator. Additionally, maintaining a good relationship with service providers allows for better communication and quicker response times, which are vital for keeping your operations running smoothly.

| Aspect | Recommendation | Frequency of Maintenance | Expected Lifespan (Years) |

|---|---|---|---|

| Regular Inspections | Conduct visual inspections for wear and tear | Monthly | 10-15 |

| Lubrication | Use high-quality lubricant on moving parts | Every 3 months | 15-20 |

| Belt Tension Adjustment | Ensure correct tension for optimal performance | Every 6 months | 10-15 |

| Replacement of Worn Parts | Replace buckets, belts, or chains as needed | As required | Varies |

| Training Employees | Provide operational training to staff | Annually | N/A |