Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

Choosing the right dust collectors is crucial for maintaining a clean and safe environment. Dust collectors play a key role in various industries, filtering harmful particles from the air. Selecting the appropriate dust collector can significantly impact efficiency and health.

When considering dust collectors, you must assess your specific needs. Different models cater to various applications, such as woodworking, metalworking, or food processing. Understanding your workspace is essential. Ensure the unit you choose can handle the expected dust load.

Additionally, pay attention to the filter types and maintenance requirements. Not all dust collectors are created equal. Some might require frequent cleaning or replacements. This can be time-consuming and costly. Sometimes, the most popular choice isn’t the best for your situation. Take time to reflect on what will work best for your space.

Dust collectors play an essential role in industrial environments. They manage airborne particles that can harm workers and disrupt processes. Properly maintaining air quality is crucial. According to the U.S. Occupational Safety and Health Administration (OSHA), harmful dust can cause serious health risks. More than 2 million workers in America face exposure to hazardous dust annually. Ensuring the right dust collector is fundamental.

When selecting a dust collector, consider the specific needs of your operation. The type of dust generated, its volume, and its particle size matter. For instance, wood dust requires different handling than metal shavings. Each material reacts differently to filtration systems. A study from the National Institute for Occupational Safety and Health (NIOSH) emphasizes that improper choices can increase health risks, leading to potential fines.

Here are some tips for choosing dust collectors: first, assess the dust type. Is it combustible? Next, evaluate airflow needs. A collector must handle the expected volume without excessive strain. Lastly, think about maintenance. Frequent cleaning can prolong the collector's life. Yet, complex systems may lead to neglect. Balancing performance with practicality is vital.

Choosing the right dust collector requires careful consideration of several key factors. One important aspect is the type of material you'll be collecting. Different dust types, such as wood or metal shavings, require specific filtration systems. Consider the size of the particles too. Larger particles may clog filters faster. This impacts efficiency and maintenance needs.

Another factor is the dust collector's airflow capacity. It should match your workspace requirements. An insufficient airflow can lead to dust build-up. This can compromise air quality. Sometimes, users underestimate this aspect. A system with too high airflow may increase energy costs unnecessarily. Striking a balance is crucial.

It's also vital to think about your layout. Space constraints can limit your dust collector options. A compact unit may be beneficial in such cases. Consider accessibility for maintenance. If it's hard to reach, it might not get the attention it needs. Reflect on these details as you make your decision. A strategic choice leads to better performance and longevity.

This chart represents key factors to consider when selecting dust collectors based on their effectiveness and typical usage scenarios.

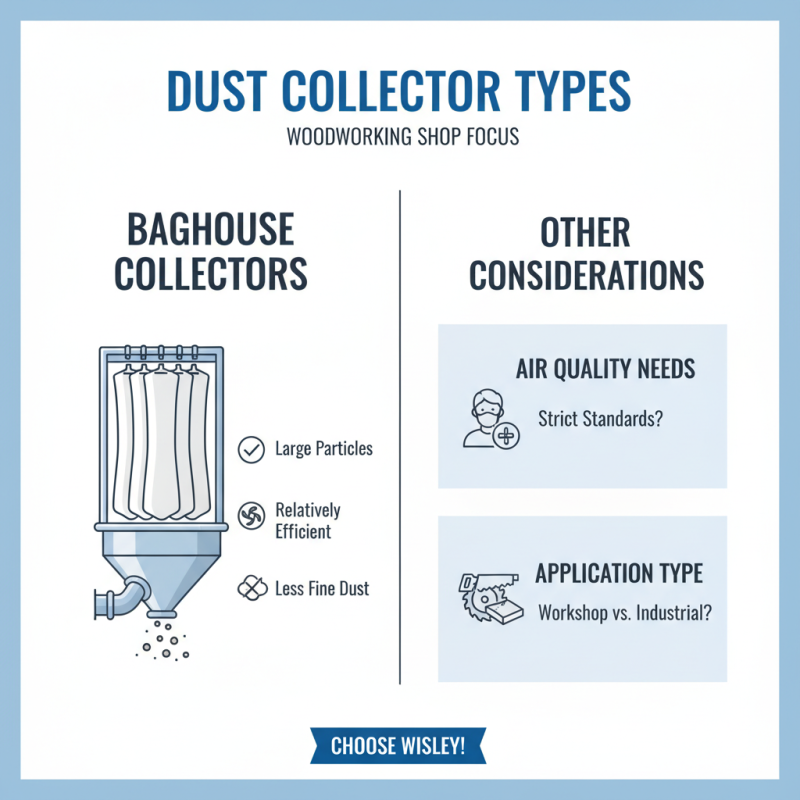

When selecting dust collectors, understanding their types is crucial. Different applications require different solutions. For woodworking shops, baghouse dust collectors often provide effective solutions. They handle large particles and are relatively efficient. However, they might not capture fine dust as well. This limitation is critical for environments requiring stringent air quality standards.

Cyclone collectors serve another purpose. They efficiently separate larger particles from the airflow. They are ideal for industries that produce heavy debris. Yet, they may struggle with fine particulate matter. If your facility generates a mix of both, consider a hybrid system. This combination can address a broader range of dust types.

HEPA filters are for spaces demanding high air cleanliness. These are suitable for healthcare and pharmaceutical applications. They capture smaller particles efficiently. However, they require more maintenance and can be costly. Make sure to evaluate your specific needs carefully. Choosing the wrong type can lead to ineffective dust control. It’s essential to reflect on your dust production levels before making a decision.

Maintaining your dust collector is crucial. Regular inspections ensure all parts work efficiently. Neglect can lead to decreased airflow and higher energy costs. A dirty filter can reduce efficiency by as much as 30%. This impacts both performance and safety.

Efficiency often relates to the system's design. Proper duct sizing matters. If ducts are too small, they can create negative pressure. This can lead to inconsistent dust removal. Studies suggest that optimizing duct design can improve efficiency by 15% or more.

Dust collectors require routine maintenance. This includes replacing filters at regular intervals. Not doing so can lead to system failure. A well-maintained system not only lasts longer but operates more effectively. Remember to track performance metrics. Keeping data will highlight when maintenance is due and identify any issues early.

| Factor | Considerations | Maintenance Tips | Efficiency Improving Methods |

|---|---|---|---|

| Filter Type | Consider the type of dust generated | Regularly check and replace filters | Choose high-efficiency filters to reduce energy costs |

| Airflow Capacity | Match airflow with the size of the workspace | Inspect airflow regularly for blockages | Use variable speed drives to optimize flow |

| Size and Space | Ensure adequate space for installation | Keep surrounding areas clear for maintenance | Design layout for optimal dust capture |

| Noise Level | Select units with acceptable noise levels | Install sound dampening materials if needed | Opt for quieter models for better workplace conditions |

| Energy Efficiency | Look for energy-efficient certifications | Maintain optimal operating temperatures | Schedule regular performance audits to enhance energy use |

When choosing a dust collector, the balance between price and quality is crucial. A low-cost model may seem appealing at first. However, hidden costs can arise. These could include maintenance, replacements, and energy efficiency. Investing in a high-quality unit might lead to savings over time. It’s essential to evaluate the total cost of ownership.

Cost considerations also involve material and performance. Cheaper units may use lower-grade materials. This can lead to frequent repairs or replacements. A durable dust collector often comes with better filtration. This directly impacts air quality. Look for specifications that align with your needs. Sometimes, you may find a mid-range unit that meets your requirements without breaking the bank.

Think about your specific applications as well. Not every dust collector suits every environment. Some require high suction power, while others focus on space saving. It can be tempting to choose a cheaper option that lacks necessary features. This can result in inefficiencies. Evaluate how often you'll use the machine, and consider future needs. A little reflection here can lead to a smarter investment down the line.