Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

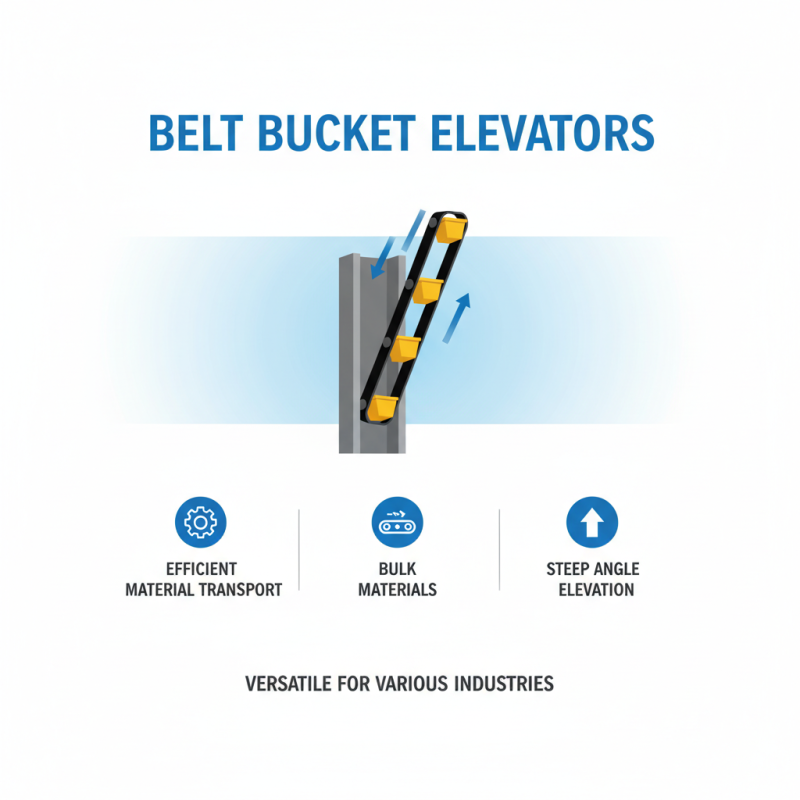

Selecting the right Belt Bucket Elevator is crucial for efficient material handling. In 2021, the global market for material handling equipment was valued at over $150 billion. Belt Bucket Elevators are versatile, catering to various industries, including agriculture and mining. The right choice can significantly impact efficiency and cost-effectiveness.

However, selecting an elevator is not always straightforward. Factors such as material type, flow rate, and environmental conditions play significant roles. According to industry studies, nearly 30% of elevator failures result from inappropriate selections. This highlights the need for careful consideration in the selection process.

Optimizing your choice is essential. Each material behaves differently under varying conditions. For instance, bulk density and moisture content can affect performance. Misunderstandings in these areas can lead to inefficiencies and costly downtimes. Therefore, gaining a deep understanding of your handling needs is paramount for successful material transport.

Belt bucket elevators are crucial in material handling. They transport bulk materials efficiently. These systems can elevate materials at steep angles. This capability makes them versatile for various industries.

Understanding your material is key. Granular substances, such as grains or fertilizers, require specific handling. The type of belt and bucket design affects performance. A 2021 industry report noted that improper design can lead to a 15% increase in maintenance costs. This statistic underscores the importance of thorough selection.

Environmental factors matter too. Dusty or wet materials can wear down the system faster. Regular checks and maintenance help mitigate these issues. A study showed that 30% of downtime is due to mechanical failures. Having a solid maintenance plan can make a significant difference. Invest time in understanding these aspects for optimal handling solutions.

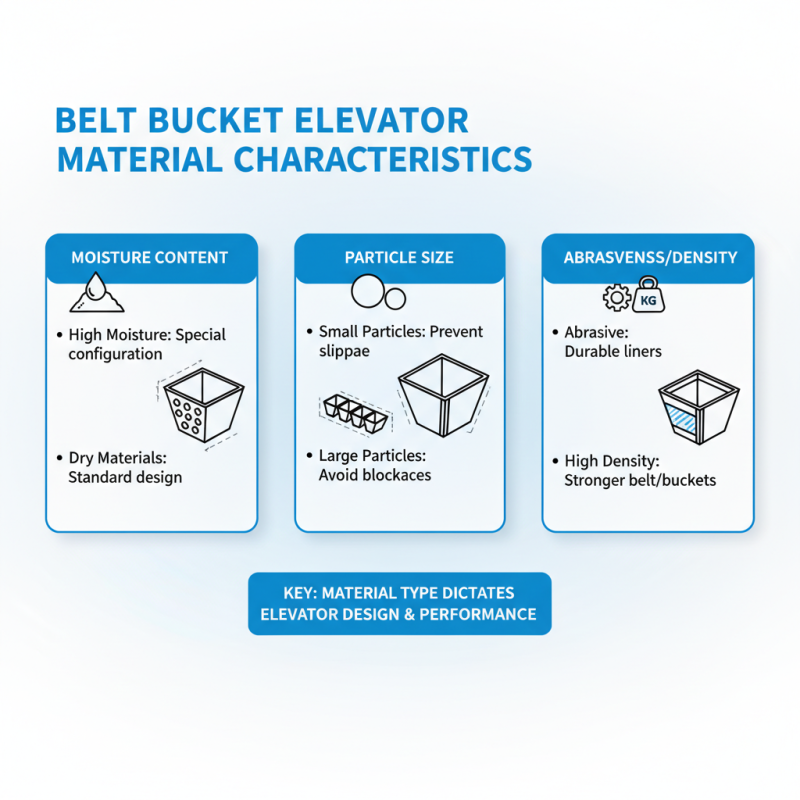

When selecting a belt bucket elevator, understanding material characteristics is vital. The type of material significantly affects the design and performance of the elevator. For instance, materials with high moisture content may require a different configuration compared to dry materials. The size of the particles also plays a crucial role. Small particles might slip through, while larger ones can cause blockages.

Consider the bulk density of your materials. Heavier materials often need more robust support structures. It is essential to evaluate the flow properties as well. Some materials flow freely, while others may clump together. This can lead to uneven distribution in the elevator. An elevator that is not tailored to the material might cause inefficiencies or even failure.

Also, think about the temperature of the materials you are handling. High temperatures could lead to material degradation or safety risks. A mismatch in temperature tolerance can become a serious flaw in your choice. It’s easy to overlook these details, but they will impact your operation. Adapting to the specific needs of your materials is not just a suggestion; it’s essential for success.

Selecting the right bucket elevator involves understanding specific capacity metrics. Metrics like flow rates, bucket size, and discharge angles are crucial. According to industry reports, flow rates can vary significantly depending on the material. For instance, a granular product may flow at 30 tons per hour. In contrast, powders might only reach 10 tons per hour at similar conditions.

Evaluating bucket elevator capacities requires assessing their construction standards. Many elevators operate under general industry standards like CEMA (Conveyor Equipment Manufacturers Association). Compliance ensures reliability and safety. However, companies sometimes overlook operating conditions. This can lead to inefficiencies or equipment failure. A critical aspect to consider is the material's bulk density. Higher densities can increase the risk of overloading.

In practice, operators often find themselves unsure of their equipment's actual capacity. Documented data may not reflect real-world performance. Regular assessments and adjustments are necessary. Even slight changes in material properties can affect output. This highlights the importance of ongoing evaluation in bucket elevator systems.

Choosing the right belt bucket elevator involves understanding the belt types: rubber, PVC, and steel cord. Each type serves specific functions. For instance, rubber belts excel in handling materials that are heavier and abrasive. They provide durability and flexibility in varying temperatures. According to industry reports, rubber belts can handle loads of over 3,000 tons per hour when designed correctly.

PVC belts, on the other hand, offer good chemical resistance and are ideal for food-grade applications. Their smooth surface reduces friction, enhancing efficiency. Research indicates that PVC belts can achieve speeds of over 6 meters per second. However, they may not always withstand heavy loads. This can lead to premature wear and tears, posing risks for material handling.

Steel cord belts are known for their strength and ability to handle extreme conditions. These belts can handle significant weights, up to 40,000 tons per hour. They are often used in mining and heavy industries. Yet, a downside exists: their rigidity can make installation and maintenance challenging. Reflecting on these factors is crucial for selecting the right belt for your needs. Each option has strengths and weaknesses that impact efficiency.

When selecting a belt bucket elevator, maintenance is crucial for durability. Regular upkeep extends the lifespan of equipment and enhances performance. According to industry reports, poorly maintained elevators can lose efficiency by up to 25%. This inefficiency leads to increased operational costs and down-time.

Tips for maintenance include: