Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

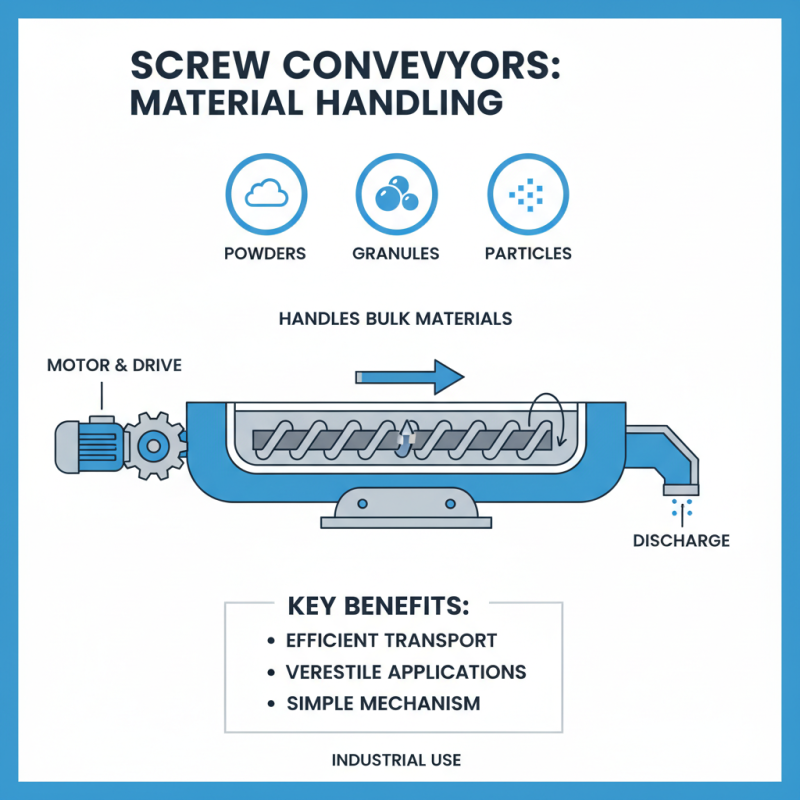

Screw conveyors are vital in material handling industries. These devices efficiently transport bulk materials across various distances. According to John Smith, a renowned expert in the field, “Screw conveyors are the backbone of modern material transport.” This statement highlights their importance in operational efficiency.

The design of screw conveyors allows for versatility in handling different materials. From grains to powders, these systems work seamlessly. However, not all installations maximize their capabilities. Some companies fail to optimize screw design and positioning, leading to inefficiencies. This oversight can result in increased operational costs.

Despite their benefits, challenges remain in using screw conveyors. Wear and maintenance are common issues that demand attention. Operators must regularly check for blockages and wear patterns. Effective training and awareness can mitigate these problems, ensuring reliable performance. Investing in quality systems is essential for long-term success. In a competitive market, understanding screw conveyors is crucial for any material handling operation.

Screw conveyors play a vital role in material handling systems. They transport bulk materials efficiently in various industries. Their design allows for easy handling of powders, granules, and small particles. The conveyor consists of a rotating helical screw that moves materials along a defined path. This simple mechanism offers great flexibility in application.

One significant advantage is their ability to convey materials at different angles. This adaptability makes them suitable for tight spaces. However, proper installation and maintenance are crucial for optimal performance. Sometimes, blockages can occur, leading to delays. Regular checks are necessary to ensure smooth operation. The effectiveness of screw conveyors depends heavily on the material's properties. Not all materials behave the same in these systems.

Understanding the limitations is equally important. For instance, they may not work well with very sticky or wet materials. In such cases, modifications may be needed. Balancing efficiency and practicality can be a challenge. By recognizing potential issues, businesses can enhance their material handling processes. These insights can drive improvements in operational reliability and productivity.

Screw conveyors play a crucial role in material handling efficiency. Their design allows for smooth transport of bulk materials. This is especially valuable in industries like agriculture and manufacturing. These conveyors can handle various materials, from grains to powders. They are compact and save space in crowded facilities.

One key advantage of screw conveyors is adaptability. They can operate on inclines and declines, which optimizes space. Their design simplifies the integration into different systems. Maintenance is generally straightforward, minimizing downtime. This is important for maintaining production schedules.

**Tip:** Regularly inspect the screws for wear and tear. A small issue can lead to bigger problems down the road.

Screw conveyors also minimize dust and spillage. This helps create a safer work environment. Keeping operations clean can be a challenge. But a well-functioning screw conveyor reduces mess.

**Tip:** Keep a maintenance log. Documenting repairs can identify patterns that need attention. Understanding these issues can improve overall efficiency. Always analyze performance over time.

Screw conveyors play a vital role in material handling due to their versatility. They are particularly effective for a range of materials, including powders, granules, and bulk solids. According to industry reports, over 40% of manufacturing processes utilize screw conveyors for efficient transport.

Food-grade materials often benefit significantly from screw conveyors. They handle dry ingredients like flour, sugar, and cornmeal gracefully. These conveyors ensure minimal contamination, vital for food safety. In the agricultural sector, they transport fertilizers and animal feeds effectively, promoting productivity. Data suggests that up to 30% of agricultural products are moved using this method.

However, not all materials are suitable for screw conveyors. Sticky or highly viscous substances can pose challenges. Additionally, the wear and tear from abrasive materials can be problematic. Regular maintenance is essential to mitigate such issues. In many cases, companies must reevaluate their choices to optimize efficiency and reduce costs. Careful consideration of the materials being handled is crucial for ensuring smooth operations.

When considering a screw conveyor, design is crucial. The dimensions of the screw play a vital role in efficiency. A proper diameter ensures optimal material flow. Too small, and materials can clog. Too large, and energy costs rise.

Material type matters, too. Different materials require specific designs. For instance, heavy materials may need reinforced screws. Lightweight materials benefit from a gentler approach. It’s a balance that can be tricky to achieve.

Placement of the conveyor affects performance. An incorrect angle can hinder movement. Likewise, the feed point needs careful positioning. If not, materials can become unevenly distributed. Observing these details can lead to better results. However, it’s easy to overlook these aspects in the design process. Continuous evaluation is key for improvement.

Screw conveyors are vital in numerous industries. They efficiently transport bulk materials like grains, powders, and aggregates. These systems minimize the risk of contamination, ensuring product quality.

In the food industry, screw conveyors handle grains and sugar. They transport these materials from storage to processing areas. A challenge arises with maintaining cleanliness in these systems. Proper design helps minimize residue buildup and ensures hygiene.

In construction, these conveyors move sand and gravel. Transporting heavy materials can be tricky. It's essential to choose the right angle and speed. Otherwise, blockages can occur. Regular maintenance is crucial to avoiding downtime. Properly functioning screw conveyors enable smoother operations in various sectors.