Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

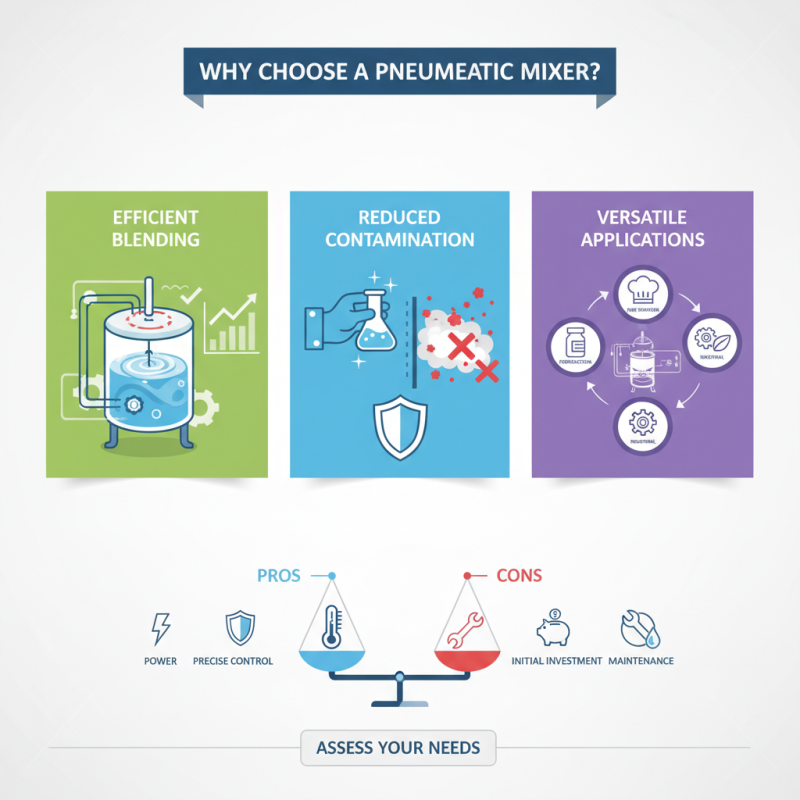

In the world of industrial mixing, choosing the right equipment is critical. Experts suggest that a "Pneumatic Mixer" can offer distinct advantages. Dr. Jane Thompson, a renowned mixing technology expert, states, "Pneumatic Mixers provide efficient blending and reduce the risk of contamination." Her insights highlight why many industries are turning to this technology.

Pneumatic Mixers utilize air pressure to create a powerful mixing action. This mechanism allows for precise control and consistent results. Industries ranging from food production to pharmaceuticals are increasingly adopting Pneumatic Mixers for their efficiency and safety. The ability to prevent product degradation during the mixing process is a significant advantage.

However, not every application requires pneumatic technology. Some might find the initial investment steep. Also, maintenance can be a concern due to the complexity of air-driven systems. Assessing your specific needs is vital. A Pneumatic Mixer might not be the perfect fit for everyone, but its benefits often outweigh potential drawbacks.

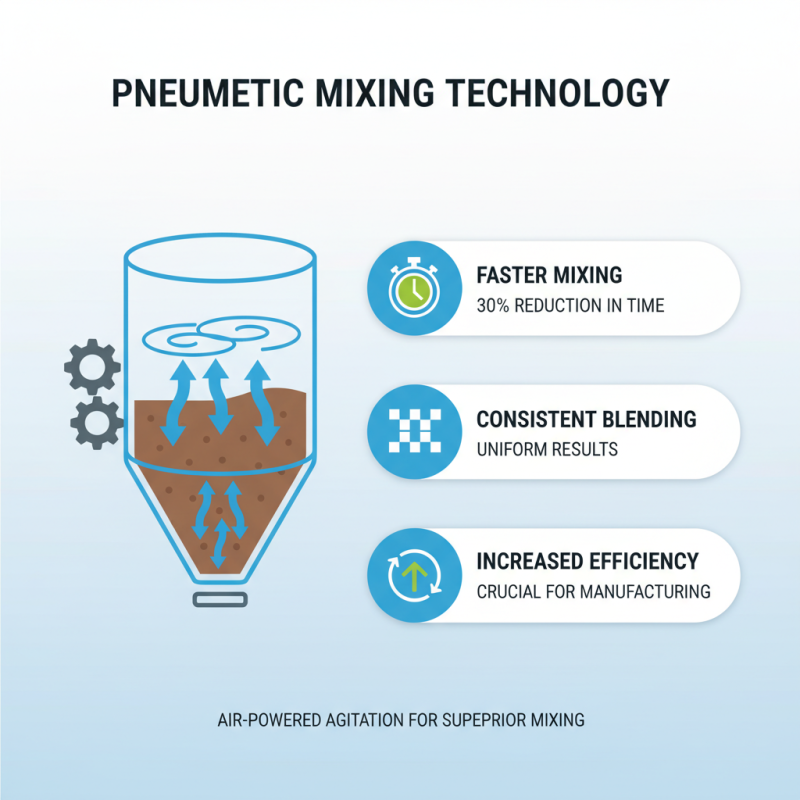

Pneumatic mixing technology utilizes compressed air to agitate and blend materials. This method offers several advantages over traditional mixing techniques. For instance, pneumatic mixers can achieve consistent and uniform mixing. According to industry reports, they can reduce mixing times by as much as 30%. This efficiency is vital in fast-paced manufacturing environments.

One of the key principles behind pneumatic mixing is the ability to adjust air pressure. By fine-tuning this pressure, operators can control the shear forces applied during mixing. This flexibility allows for the effective blending of a range of materials, from liquids to slurries. Tips: Always monitor air pressure closely. It affects the outcome.

However, there are challenges. Not all pneumatic mixers handle viscosity well. This can lead to imperfect mixes. Operators might need to experiment to find the right settings. Tips: Keep a log of pressure settings for different materials. It helps in future processes. Adopting pneumatic mixing technology requires reflection and adaptation. Each situation is unique, and understanding the intricacies of this technology is crucial for achieving optimal results.

Pneumatic mixers are gaining traction in industrial settings. Their efficiency in blending materials is notable. Reports show that these mixers can enhance production rates by up to 30%. This improvement is significant for companies looking to optimize their operations.

One key advantage is their adaptability. Pneumatic mixers operate effectively with various materials, including fragile ones. They reduce the risk of damaging delicate components during mixing. This versatility makes them suitable for industries like food and pharmaceuticals. However, they require regular maintenance to ensure peak performance. Overlooking this can lead to inefficiencies or downtimes.

Additionally, pneumatic mixers can function in hazardous environments. They eliminate the risk of electric sparks, making them safer for flammable substances. Approximately 20% of workplace incidents involve explosions from mixing processes. Again, regular checks are essential. Neglecting them can compromise safety measures, especially in high-stakes environments.

Pneumatic mixers have gained traction in various industries due to their efficiency and cost-effectiveness. According to industry reports, these mixers can improve mixing times by up to 30%. This enhancement leads to lower operational costs and increased productivity. Data also shows that businesses can save approximately 15% on energy costs when using pneumatic systems. The reliance on compressed air provides a powerful yet simple solution for mixing needs.

Tips: Regular maintenance of pneumatic mixers is essential. Inspect air hoses and regulators to avoid disruptions. Small issues can escalate if not addressed promptly.

Moreover, pneumatic mixers maintain consistent performance over time. This reliability is crucial in high-demand settings. However, it’s important to note that initial setup and air supply requirements can present challenges. Training personnel to effectively manage these systems is key.

Tips: Consider a pilot testing phase. Testing with small batches helps determine effectiveness before full-scale implementation. Be sure to assess the adaptability of the mixer to your specific requirements.

Pneumatic mixers offer distinct advantages compared to traditional mixing methods. These mixers use compressed air for agitation, which can be more efficient. According to a recent industry report, pneumatic mixers can reduce blending time by up to 40%. This speed is crucial in high-demand production environments.

In contrast, traditional mixers often rely on mechanical systems. While these methods are effective, they can produce inconsistent results and require more manual oversight. The American Chemical Society notes that variations in speed and torque can lead to uneven mixtures, affecting product quality. In addition, traditional mixers can generate excess heat, which may compromise sensitive materials.

Furthermore, pneumatic mixers are often lighter and easier to maintain. Their fewer moving parts mean less wear and tear. A study from the International Journal of Industrial Engineering highlights that pneumatic systems experience 30% lower maintenance costs over time. However, they may have limitations in specific applications. Not all materials are suitable for pneumatic processes. It's important to evaluate the specific requirements of your project when choosing a mixing solution.

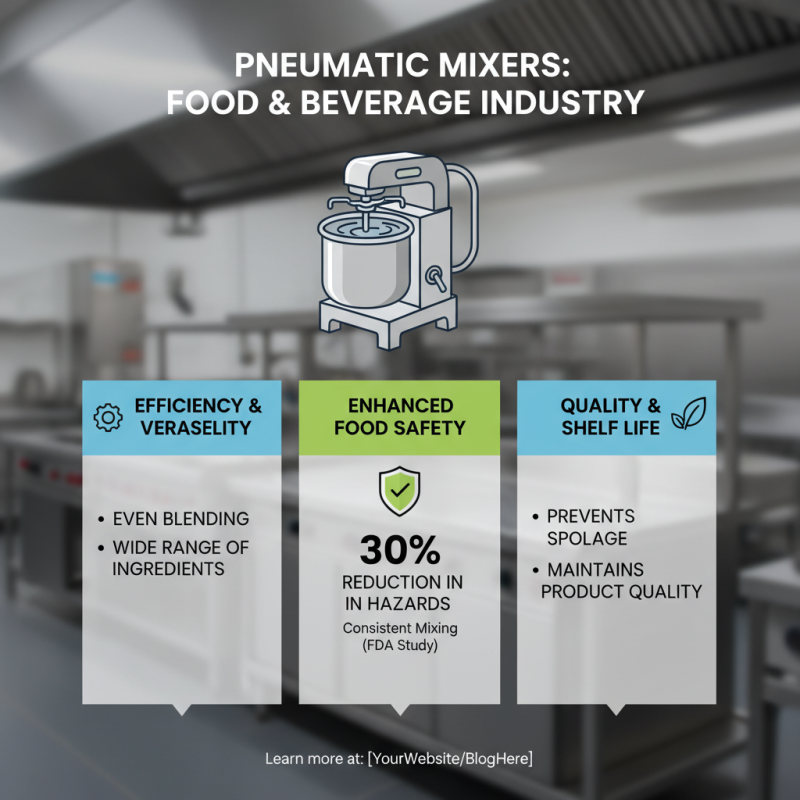

Pneumatic mixers have gained traction across multiple industries for their efficiency and versatility. In the food and beverage sector, for instance, these mixers provide crucial assistance with blending ingredients evenly. A study from the Food and Drug Administration showed that consistent mixing can reduce food safety hazards by up to 30%. This is essential in preventing spoilage and maintaining quality.

In the pharmaceutical industry, pneumatic mixers support the production of APIs and formulations. The American Chemical Society indicates that proper mixing is vital for drug efficacy, with inconsistencies potentially affecting therapeutic outcomes. Pneumatic mixers offer a high degree of control over the mixing environment, helping to achieve the exact consistency required.

However, not all mixing processes are perfect. Some users report challenges with achieving homogeneity when dealing with highly viscous materials. While pneumatic mixers excel in many applications, their suitability can vary based on the specific material being mixed. It’s essential to assess each situation carefully. Balancing efficiency with quality requires a nuanced approach.