Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

The plastic industry is experiencing rapid growth. According to the Plastics Industry Association, the U.S. plastics market is projected to reach $441 billion by 2025. A vital component of this sector is the Plastic Sheet Extruder. This machine plays a crucial role in producing various plastic sheets used in packaging, construction, and other applications.

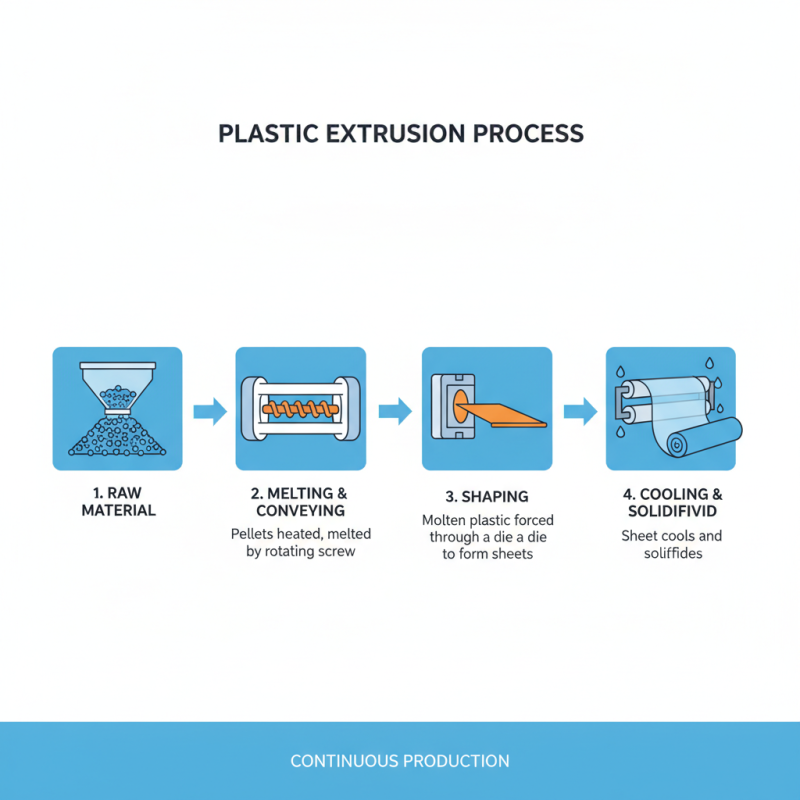

Plastic sheet extruders work by melting plastic pellets and forming them into continuous sheets. This process is efficient and cost-effective, meeting the demands of manufacturers and consumers alike. However, the reliance on such machinery is not without challenges.

Power consumption, waste, and material compatibility are significant concerns when using plastic sheet extruders. As the industry evolves, improvements are necessary to enhance sustainability. By adopting innovative technologies and practices, manufacturers can reduce their environmental impact while maintaining product quality. Understanding the workings of a plastic sheet extruder helps in recognizing both its benefits and its limitations.

A plastic sheet extruder is a machine that creates large, flat sheets from plastic materials. This process is essential in various industrial applications. The extruder heats plastic pellets until they become malleable. Afterward, the material is forced through a die, shaping it into a continuous sheet.

The machine operates through a set of screws that mix and push the plastic. This mixing ensures an even consistency, critical for quality sheets. Extrusion isn’t perfect; it can lead to irregular thicknesses or bubbles. Operators must monitor processes closely to catch these defects early.

Tips: Always calibrate the temperature settings. Too hot can cause degradation, too cold can create inconsistency. Regular maintenance is crucial. Check for wear on the screws and die, as they affect output quality. Taking these precautions can improve production efficiency.

A plastic sheet extruder is an essential machine in the manufacturing industry. Its main function is to convert raw plastic pellets into sheets of various thicknesses and sizes. Understanding the key components of this machine is crucial for optimal performance.

The hopper is where raw plastic materials are loaded. It feeds the pellets into the extrusion system. This part is simple but critical; any blockage can disrupt production. Next is the barrel and screw assembly. The screw rotates and pushes the pellets forward. As they progress, they are heated and melted. This process can be tricky. If temperatures are not correctly maintained, the plastic may degrade.

After the melting process, the molten plastic enters the die. The die shapes the material into a sheet. The cooling system then solidifies the sheet, ensuring it retains its form. While these components seem straightforward, their alignment and interaction can lead to many challenges. Regular maintenance and adjustments are necessary to avoid defects in the final product.

| Component | Function | Material | Typical Size (mm) |

|---|---|---|---|

| Hopper | Stores raw materials for feeding into the extruder | Plastic pellets | 500 x 400 x 600 |

| Screw | Moves and melts the plastic through the barrel | Steel | Ø 60 - 120 |

| Barrel | Heats the plastic pellets for melting | Aluminum or Steel | 1500 |

| Die | Shapes the melted plastic into sheets | Steel | Varies based on product |

| Cooling System | Cools the extruded sheet to maintain shape | Water or air | N/A |

| Pull Rollers | Pulls the sheet through the system at a consistent speed | Rubber or plastic | Varies based on machine |

| Cutter | Cuts the extruded sheet to desired lengths | Steel | N/A |

The extrusion process begins with raw plastic pellets. These pellets are heated in a barrel to form a molten state. A rotating screw forces the melted plastic through a die, shaping it into sheets. This process allows for continuous production. The sheet cools as it exits the die, creating a solid material.

Tips: Ensure the temperature is consistent. Variations can cause defects. Also, monitor the pressure in the extruder. High pressure may lead to blockages.

Cooling is essential. As the sheets cool, they can warp if not managed properly. It is crucial to maintain a uniform cooling rate. Uneven cooling may cause curling or distortion. Regular checks on equipment can help avoid these issues.

In this process, attention to detail matters. Imperfections may arise from inconsistent materials or machine settings. Experimenting with different parameters can yield better results. Consistency is key, but flexibility allows for improvements. Proper training on machinery use can also enhance output quality.

Plastic sheet extrusion offers diverse applications across various industries. It transforms raw plastic into sheets of specific thickness and size. One notable application lies in packaging. Many food products use plastic sheets for protection and preservation. Clear plastic sheets allow visibility while providing a barrier against moisture. This combination helps extend shelf life significantly.

Another significant application is in construction. Plastic sheets, such as polyethylene, serve as vapor barriers and help manage moisture. They are commonly used in foundation work and roofing. Protecting insulation from moisture damage prevents costly repairs later on. However, some drawbacks exist, such as environmental concerns regarding plastic waste.

Moreover, plastic sheets are essential in the automotive industry. They produce interior components and dashboards. Lightweight plastic contributes to fuel efficiency. Yet, the durability of these components can sometimes be questioned. The balance between weight and strength needs ongoing inspection. Each application highlights the vital role of plastic sheet extrusion while also urging for sustainable practices.

Plastic sheet extruders play a vital role in manufacturing. They convert raw plastic pellets into large sheets used in various industries. The process begins with heating the pellets until they melt, then forcing the molten plastic through a shaped die. This leads to a continuous sheet formation.

The benefits of using a plastic sheet extruder are substantial. Firstly, it offers high efficiency. Businesses can produce large quantities in a short time. This reduces labor costs significantly. Moreover, the extruded sheets can be customized in thickness and color. Manufacturers can create products tailored to specific needs.

However, the technology is not without challenges. Quality control can be tricky. Small variations in temperature or pressure can impact the final product. It’s essential to monitor the process closely. Additionally, the initial investment in equipment can be high. Businesses must weigh the benefits against costs.

This bar chart illustrates the annual production output of plastic sheets (in metric tons) from 2018 to 2023 using a plastic sheet extruder. The data reflects the increasing capacity and efficiency of the technology over the years.