Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

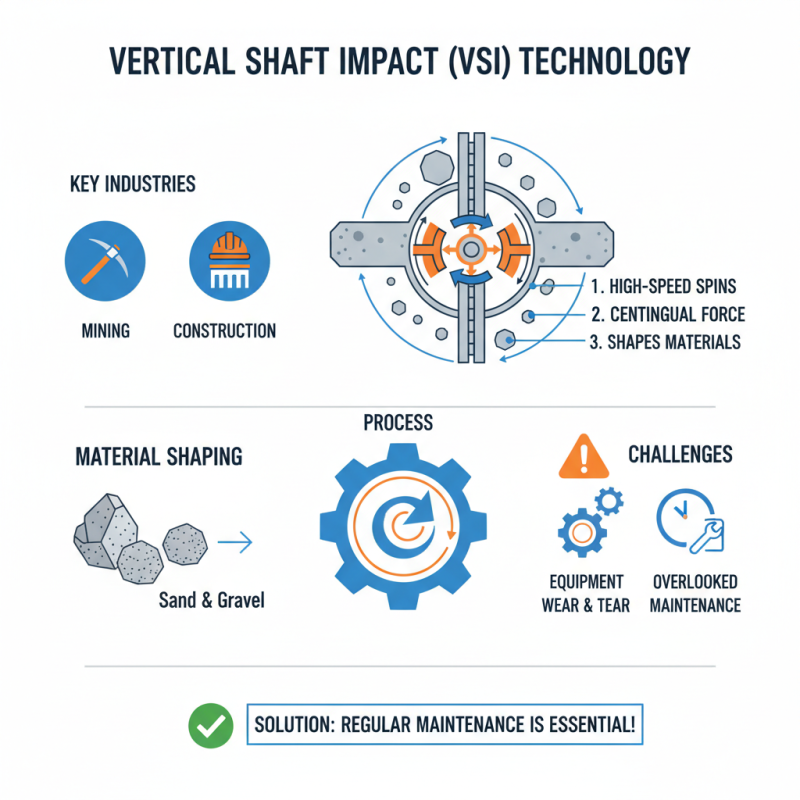

Vertical Shaft Impact (VSI) crushers are crucial in the mining and construction industries. They enhance the processing of both hard and soft materials. According to a recent report by Market Research Future, the global VSI market is projected to grow by over 6% annually until 2025. This underscores the need for optimizing VSI performance.

Efficient VSI operations can lead to a significant increase in production. A study from the Mining Industry Data Report indicates that improved VSI technologies can raise output by up to 30%. However, operational challenges often remain. Many facilities still struggle with maintaining consistent efficiency.

Understanding the factors affecting VSI performance is essential. These include material characteristics, rotor speed, and maintenance practices. It’s clear that a focus on optimization could yield better results. Yet, despite available data, some operators fail to adapt to new techniques. Continuous evaluation and adjustments are necessary. Learning from both successful cases and shortcomings can drive improvement. With the right strategies, the benefits are achievable.

Vertical Shaft Impact (VSI) technology is crucial in various industries, including mining and construction. It excels at shaping materials like sand and gravel. The process involves high-speed rotor spins, which create intense centrifugal forces. This action breaks down materials into desired sizes. However, managing the wear and tear of the equipment can be a challenge. Regular maintenance is essential but often overlooked.

Operators must monitor the performance closely. Understanding the feed material is vital to optimize efficiency. Variations in size and moisture content can impact output. A personal reflection: adapting to these changes requires experience and flexibility. It's easy to miss key indicators, leading to unnecessary downtime or reduced product quality.

Additionally, achieving the right configuration can be complex. The angle of the rotor and the speed settings significantly influence results. Adjusting these parameters for specific applications can be tricky. Sometimes, trial and error is the only way to find the perfect setup. Rethinking strategies and embracing data analysis can lead to improved performance. Recognizing these factors is essential for success in using VSI technology effectively.

Vertical Shaft Impact (VSI) crushers are vital for producing high-quality materials in construction and mining. The performance of a VSI depends heavily on various factors. Among them, rotor design is crucial. A well-optimized rotor can enhance throughput by up to 25%, as reported by the International Journal of Integrated Engineering.

Material characteristics also play a significant role. The hardness and size of the input material affect reduction efficiency. Studies indicate that harder materials can lead to increased wear on the machine, which may reduce overall effectiveness. In some cases, operators may overlook the grade of materials, leading to suboptimal performance.

Furthermore, the angle of the feed and the speed of the rotor are major contributors to VSI performance. An incorrect angle can lead to excessive energy consumption. According to industry reports, adjusting the rotor speed can optimize the crushing process. But, operators must monitor wear closely, as high speeds may increase the risk of component damage. Continuous assessment is essential in achieving the desired outcomes.

When optimizing vertical shaft impact (VSI) performance, maximizing material feed efficiency is key. A report by the Mining Industry Evaluator shows that proper feed rates can improve output by 20%.

Adjusting the feed size is essential. Too large can cause blockages, while too small may lead to excessive wear.

Aim for a balanced feed that suits your equipment.

Tip: Regularly check your feed material size. Maintain a consistent feed size to avoid fluctuations in performance. This can help reduce downtime during production.

Monitoring the moisture content in your materials also plays a crucial role. High moisture levels can cause clumping, leading to uneven feed rates.

Studies indicate that maintaining moisture below 5% can enhance the overall efficiency by up to 15%.

Tip: Invest in a moisture measurement system. This can help you make real-time adjustments, optimizing the feed quality.

Understanding the characteristics of your materials is vital. Each type has unique properties that can affect how they perform in a VSI.

Some materials may require more frequent adjustments. It is important to adapt to these changes promptly to maintain efficiency. Reflecting on these aspects can lead to valuable improvements in your operations.

Optimizing the performance of a Vertical Shaft Impact (VSI) crusher requires careful attention to various operating parameters. These adjustments can significantly enhance output quality and efficiency. One crucial aspect is controlling the rotor speed. Increasing the rotor speed can improve the material's impact energy, but too high a speed may lead to excessive wear on parts. Finding the right balance is key.

Another critical factor is the feed size. Smaller feed particles can enhance the crushing process, but excessive fines can reduce overall performance. Aim for a consistent feed size to maintain efficiency. Monitor the feed rate closely; too much material can result in blockage and reduced output.

Tips for optimization include:

- Regularly check and calibrate the equipment to ensure precise settings.

- Experiment with different material types to understand how they interact during processing.

- Maintain a log of adjustments and their outcomes to identify patterns over time.

Adjusting these parameters requires ongoing evaluation. Each change may lead to unexpected consequences. Stay adaptable and be prepared to iterate on your strategies. Through careful monitoring and tweaking, you will find the optimal settings for your VSI.

| Operating Parameter | Recommended Range | Impact on Performance |

|---|---|---|

| Rotor Speed (RPM) | 1200 - 1500 | Increases material throughput and energy efficiency. |

| Feed Rate (ton/h) | 50 - 100 | Optimizes particle size distribution and reduces overload risks. |

| Screen Size (mm) | 5 - 10 | Improves material separation and final product quality. |

| Motor Power (kW) | 75 - 150 | Higher power leads to greater impact energy and improved crushing. |

| Cavity Type | Deep vs. Shallow | Deep cavities enhance material reduction and improve shape. |

Regular maintenance is essential for vertical shaft impact (VSI) performance. Studies indicate that poorly maintained VSIs can lead to a 30% decrease in efficiency. Simple checks can prevent this drop. Monitoring wear parts like rotor tips and anvils is crucial. Replacing them at recommended intervals can dramatically enhance performance.

Moreover, lubrication plays a significant role. Inadequate lubrication can cause overheating and premature failure. Reports show that 40% of VSI failures stem from lubrication issues. Regularly cleaning and replacing oil can increase reliability by up to 20%. Operators must stay alert to these details; neglect can be costly.

Dust and debris often go unnoticed. They can accumulate and affect the VSI's performance. A study found that allowing material buildup can reduce output by 15%. Implementing routine cleanings is vital. Yet, many operators overlook this step. Reflecting on maintenance practices can lead to better outcomes over time.