Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In the competitive world of aggregate production, optimizing the performance of Vertical Shaft Impact (VSI) crushers is crucial. According to industry expert John Smith, "Efficient VSI operation is key to achieving maximum output." His insight emphasizes the importance of this equipment in the mining and construction sectors.

Vertical Shaft Impact crushers have unique characteristics that boost their performance. They can create high-quality aggregates with desired shapes and sizes. However, many operators face challenges in maintenance and operation efficiency. A commonly overlooked aspect is the importance of regular wear monitoring and proper material selection. These factors significantly influence the output quality and quantity.

Operators often grapple with the balance between speed and material feed rates. Understanding this balance is essential for optimizing VSI performance. Continuous learning and adaptation can lead to efficiency gains. Each component in a VSI has a role, and neglecting any aspect can lead to suboptimal performance. It's clear that looking to experts and embracing best practices can provide pathways to improvement.

Vertical Shaft Impact (VSI) crushers are crucial in the mineral processing industry. They use high-speed rotors to accelerate material. This process results in high-efficiency crushing. Proper understanding of their principles can significantly improve performance. A recent industry report highlights that optimal rotor speed enhances energy efficiency by 10-15%. This insight is vital for operators aiming for maximum productivity.

Keeping the equipment in good condition is key. Regularly checking wear parts can avoid unexpected downtime. Operators should consider the gradation of materials. Optimal feed size can lead to better crushing results. Avoiding larger particles than recommended can make a big difference. Data suggests that 50% of operators do not monitor feed size, leading to inefficiencies.

Tips: Maintain a clean crushing chamber to prevent buildup. Also, adjust the specific gravity of materials. This can help improve overall performance and energy consumption. Refining settings based on material type can enhance output. Remember, improper setup can lead to excessive wear and costly repairs. Monitoring these factors is essential for optimal performance.

| Parameter | Description | Optimal Range | Impact on Performance |

|---|---|---|---|

| Feed Size | Maximum size of material entering the crusher. | < 50 mm | Directly influences crushing efficiency and product size. |

| Rotor Speed | Speed at which the rotor spins, impacting impact energy. | 1200 - 1500 RPM | Affects particle velocity and crushing effectiveness. |

| Inlet Angle | Angle at which material enters the crusher. | 30° - 45° | Influences material flow and impact distribution. |

| Material Type | Physical properties of the material being processed. | Hardness: 6 - 8 Mohs | Determines wear rate and crushing efficiency. |

| Product Gradation | Distributions of sizes of the output material. | Optimal: 0 - 5 mm for fine aggregates | Affects marketability of the final product. |

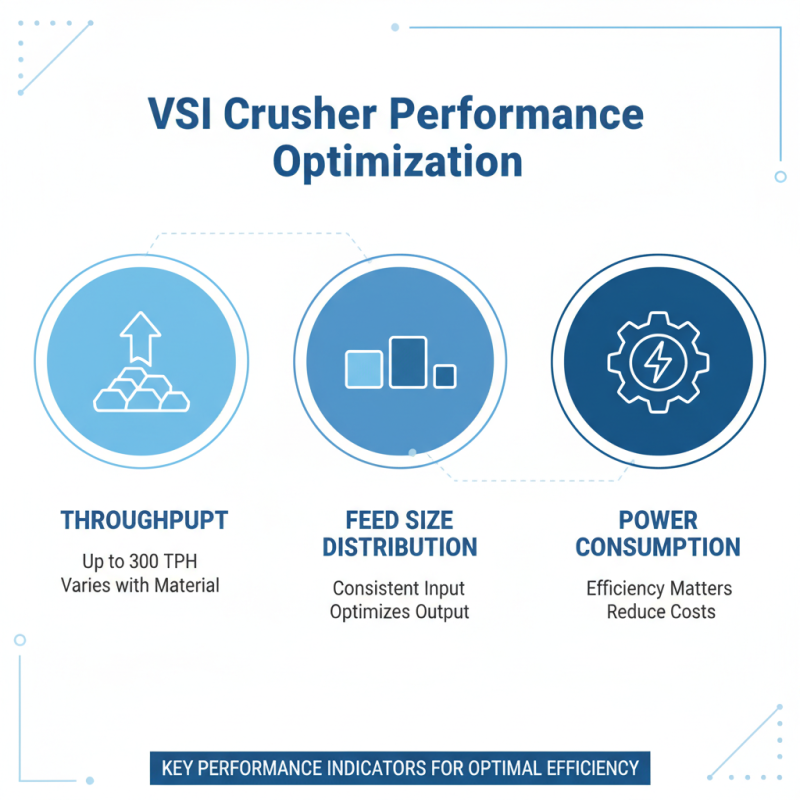

When optimizing the performance of a vertical shaft impact (VSI) crusher, understanding key performance indicators (KPIs) is essential. Metrics such as throughput, feed size distribution, and power consumption provide insights into efficiency and output. For instance, industry studies show that optimal throughput can reach up to 300 tons per hour under ideal conditions. However, real-world figures often vary, reflecting changes in materials or operating techniques.

Another crucial KPI is the product gradation. A well-optimized VSI should produce a consistent particle size distribution, typically within 0 to 3 mm for fine aggregates. Yet, achieving this uniformity can be challenging. Inconsistent feed quality often leads to deviations, impacting the final product. Additionally, power consumption during operation often exceeds expected levels, suggesting the need for operational adjustments.

Regular monitoring of these KPIs can reveal performance gaps. By analyzing data, operators will discover areas for improvement. Sometimes, even minor adjustments in the feed or operational settings yield significant results. Continuous reflection on these indicators ensures that the VSI crusher operates at its peak efficiency. Balancing these performance metrics, while acknowledging the complexities of real-life applications, is vital for achieving higher outputs and maintaining a competitive edge.

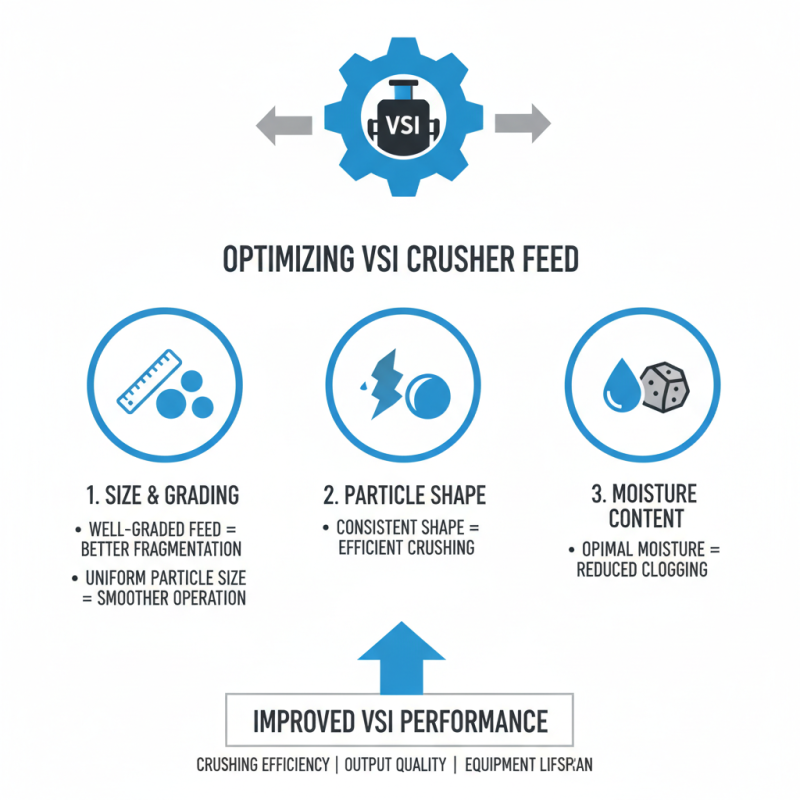

Optimizing feed material characteristics is crucial for improving the performance of a vertical shaft impact crusher (VSI). The nature of the input material directly affects crushing efficiency. For instance, the size, shape, and moisture content of the feed can significantly influence the output. A well-graded feed helps achieve better fragmentation. Ideally, the feed material should have a consistent particle shape. This uniformity helps the crusher operate more smoothly and effectively.

**Tip:** Consider reducing moisture in the feed material. Excess moisture can lead to clumping and uneven flow. Clumped materials are harder to crush. Moreover, this can lead to wear and tear on the equipment. It may compromise the quality of the final product.

Another critical aspect is the feed size. Too large pieces can cause blockages and need more energy to crush. Conversely, overly small pieces may not provide adequate input for effective crushing. Experimenting with feed size can reveal optimal conditions. Be prepared for adjustments, as different materials often yield different results.

**Tip:** Regularly test and monitor feed characteristics. Small changes can lead to significant improvements. Unpredictable feed can lead to poor performance. Make it a habit to analyze material properties before processing.

To enhance the longevity of vertical shaft impact (VSI) crushers, regular maintenance is essential. Inspecting wear parts frequently can identify potential issues before they become major problems. Regular cleaning of the rotor and impact chambers prevents the accumulation of debris. This step improves performance and prolongs the equipment's life.

Tips: Schedule weekly inspections for your VSI crusher. Also, keep a close eye on the lubrication system. Proper lubrication reduces friction and wear on moving parts. Regularly replace oil to ensure efficient operation. Doing so may seem tedious, but skipping it can lead to costly repairs.

Another vital maintenance strategy involves monitoring operational settings. Adjustments that are too aggressive can stress your equipment. Listen for unusual noises or vibrations; these may indicate misalignment or imbalance. Regularly review your maintenance logs. They can provide insight into recurring issues. Addressing these early can prevent future breakdowns.

The vertical shaft impact crusher (VSI) plays a crucial role in construction and mining industries. Optimizing its performance can lead to improved efficiency and cost-effectiveness. Real-time performance monitoring is essential for keeping operations smooth. Using advanced technologies, such as IoT sensors, allows for better data collection and analysis. This technology makes it easier to spot issues before they escalate.

Integrating these technologies helps operators track vital metrics. For instance, monitoring vibration levels, temperature, and throughput provides instant feedback. However, implementing real-time monitoring can present challenges. Data overload can lead to confusion. It’s important to filter relevant information and focus on critical performance indicators.

Automating responses based on real-time data can also enhance operational efficiency. Yet, complete automation might overlook subtle human insights. Regular human intervention is still needed for comprehensive analysis. Balancing technology with human expertise can enhance the overall effectiveness of performance monitoring.

This chart illustrates the performance metrics of a Vertical Shaft Impact Crusher over a series of operational scenarios. The metrics include throughput (tonnes/hour), energy consumption (kWh/ton), and wear rate (kg/ton). By applying advanced technologies for real-time monitoring and control, these performance metrics can be effectively optimized.