Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In the dynamic landscape of manufacturing, selecting the appropriate Plastic Sheet Extruder is crucial for optimizing production efficiency and quality. According to a report by the Plastic Industry Association, the U.S. plastic sheet market is projected to reach $12.5 billion by 2025, highlighting a significant demand for advanced extrusion technology. This underscores the importance of not only choosing the right machinery but also understanding the specific needs of your manufacturing processes.

Industry expert Dr. Emily Harper emphasizes that “Investment in the right Plastic Sheet Extruder can substantially reduce waste and improve overall production turnaround time.” With numerous options available, manufacturers must carefully consider factors such as material compatibility, extrusion capacity, and technological advancements to ensure their equipment aligns with current industry standards and future growth potential. The right choice can lead to enhanced product quality, reduced operational costs, and a competitive edge in the ever-evolving market.

Plastic sheet extrusion technology is a crucial process in the manufacturing sector, allowing the creation of flat plastic sheets used in various applications. This process involves melting plastic pellets and forcing them through a die, which shapes the molten material into a flat sheet. Understanding the fundamentals of this technology is essential for manufacturers looking to choose the right plastic sheet extruder to meet their specific needs.

One of the key factors in plastic sheet extrusion is the selection of materials. Different types of plastics, such as polyethylene, polypropylene, and polystyrene, each have unique properties that influence the extrusion process and the final product's characteristics. Additionally, the extruder's design, including elements like the screw configuration and temperature control, plays a significant role in determining the efficiency and quality of the output. Familiarity with these basics enables manufacturers to evaluate their options more effectively and ensure that they invest in the right equipment for their production requirements.

| Specification | Description | Application | Material Compatibility | Production Capacity (kg/h) |

|---|---|---|---|---|

| Single Screw Extruder | Simple design, cost-effective, suitable for basic applications. | Sheet production, general plastics. | PVC, PS, ABS | 100 - 300 |

| Twin Screw Extruder | Advanced mixing capabilities, ideal for complex formulations. | High-performance sheet applications. | ABS, PC, blends | 200 - 600 |

| Co-Extruder | Multiple layer production for enhanced properties. | Packaging film, specialized sheets. | PET, PE, multi-materials | 150 - 450 |

| Sheet Die Extruder | Specially designed for sheet formation with uniform thickness. | Large format sheets for construction. | HDPE, LDPE, PP | 300 - 800 |

When selecting the right plastic sheet extruder for your manufacturing needs, it's essential to start by identifying your specific requirements. Factors such as the type of plastic material you intend to use, the thickness and dimensions of the sheets, as well as production volume, play a significant role in narrowing down your options. According to a recent industry report by Grand View Research, the global plastic sheet market is projected to reach $55 billion by 2027, showing a robust annual growth rate of over 5%. This growth highlights the increasing demand for high-quality extrusion processes tailored to diverse applications, from packaging to construction.

Understanding the nuances of your manufacturing process is critical. For instance, if you're focused on producing sheets for food packaging, considerations like hygiene and product safety standards must influence your choice of extruder. A study published in the Journal of Applied Polymer Science notes that the optimal processing temperature range for common thermoplastics can vary significantly, thus impacting the quality and properties of the finished product. Furthermore, evaluating automation level is also vital, as more advanced extruders can enhance efficiency and reduce labor costs, aligning with the sector's trend towards more automated facilities.

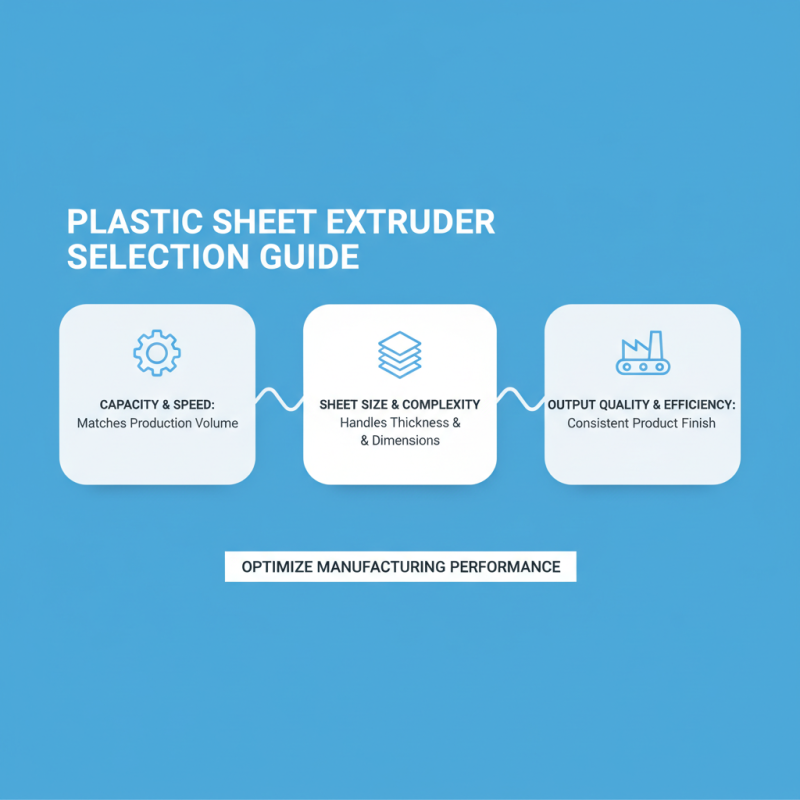

When selecting a plastic sheet extruder for your manufacturing needs, several key features deserve careful consideration to ensure optimal performance and efficiency. First, the extruder's capacity is crucial; it should match your production volume demands. Consider the line speed and output rate, as these metrics will determine how quickly you can meet customer orders. Additionally, the size and complexity of the sheets you plan to produce should influence your choice, ensuring that the extruder can handle different thicknesses and dimensions without compromising quality.

Another significant aspect to evaluate is the type of screw design used in the extruder. A well-designed screw can enhance material mixing, melting efficiency, and overall extrusion quality. Look for options that offer adaptability for various materials, as versatility can be vital for expanding your product range in the future. Moreover, temperature control systems should not be overlooked; effective temperature management can prevent material degradation and improve the consistency of your output. By focusing on these essential features, you can select an extruder that aligns with your specific manufacturing requirements and contributes to your overall production success.

When selecting a plastic sheet extruder for manufacturing, it’s essential to compare the various types available on the market. The primary classifications include single-screw extruders, twin-screw extruders, and co-extruders.

Single-screw extruders are widely used for their simplicity and cost-effectiveness. They excel in processing a wide range of thermoplastics, making them suitable for low to medium production runs. However, their limitations in mixing capabilities might affect the quality of finished products requiring specific properties.

On the other hand, twin-screw extruders offer superior mixing and homogenization features, making them ideal for processing complex materials that include additives or blends. This flexibility enables manufacturers to create specialized products tailored for specific applications.

Co-extruders, which combine two or more extruders, allow for the production of multilayer sheets. This capability is vital when different materials need to be combined to enhance properties such as barrier performance, strength, or aesthetic appeal.

Ultimately, the choice of extruder type will depend on the specific manufacturing requirements, including the desired material properties, production volume, and budget constraints. By carefully assessing the strengths and limitations of each extruder type, manufacturers can make informed decisions that align with their operational needs and goals.

When selecting a plastic sheet extruder, evaluating the cost-effectiveness and maintenance needs is crucial for ensuring optimal production efficiency. Cost-effectiveness involves analyzing both the initial investment and the long-term operating costs. A more expensive extruder may offer advanced features and higher output, thus offsetting its cost through improved productivity and reduced material waste. It is essential to perform a cost-benefit analysis to ensure that the performance gains justify the expense, considering factors such as energy consumption, labor costs, and potential downtime.

Maintenance needs significantly influence the overall operational efficiency of the extruder. Regular maintenance can prevent costly breakdowns and extend the lifespan of the machine. It is essential to assess how easy it is to access components for routine checks and replacements. Some extruders may require specialized tools or training to maintain, increasing labor costs and downtime. On the other hand, models designed for easier maintenance can contribute to a more efficient production cycle, allowing manufacturers to respond swiftly to issues and minimize disruptions. Choosing a machine with well-documented support and easily replaceable parts can help ensure that maintenance remains manageable and cost-effective in the long run.