Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

Choosing the right Plastic Sheet Extruder can be challenging. The market is flooded with options. Each machine offers unique features. Understanding your specific needs is crucial.

John Doe, a plastic manufacturing expert, once stated, “Selecting the right extruder defines your production quality.” This highlights the importance of making an informed decision. Factors like material type, thickness, and production speed matter. It's not just about the machine; it’s about the end product.

Many manufacturers overlook these aspects. They might choose a Plastic Sheet Extruder based on price alone. This can lead to inefficiencies. Some might find themselves coping with frequent breakdowns. Reflecting on your choices is essential for long-term success. Choosing wisely today can enhance your output tomorrow.

Identifying production requirements is crucial when selecting a plastic sheet extruder. Start by considering the thickness of the sheets you plan to produce. Different applications, from packaging to automotive components, require varying thicknesses. For example, thinner sheets (1-3 mm) are often used for packaging, while thicker sheets (over 5 mm) cater to more robust applications. According to industry reports, around 30% of manufacturers face challenges due to incorrect thickness selection.

Next, evaluate the desired output volume. A high-output line can produce between 100-500 kg/hour depending on the materials used. If your production capacity is low, a smaller extruder may suffice. However, be wary of bottlenecks. Many companies underestimate the need for flexibility in production. A common pitfall is not factoring in material variations. Not all materials flow the same, which can affect production efficiency.

Consider your material compatibility as well. Different plastics require specific extruder designs. Polyethylene, for instance, behaves differently than polycarbonate. A mismatch can lead to poor quality sheets or increased waste. Research suggests that nearly 40% of extrusion failures are related to material choice. A careful assessment of your production requirements will help narrow down the right extruder configuration and avoid costly mistakes.

| Dimension | Description | Recommended Capacity (kg/h) | Material Types | Applications |

|---|---|---|---|---|

| Small Scale | Ideal for startups and low-volume production. | 50-100 | PVC, PET | Retail packaging, prototypes |

| Medium Scale | Suitable for moderate production and diverse applications. | 100-300 | HDPE, LDPE | Containers, trays, general packaging |

| Large Scale | Designed for high-output production and efficiency. | 300+ | ABS, Polycarbonate | Automotive parts, large sheets |

| Custom Solutions | Tailored extruders for specific needs. | Varies | Various materials | Specialized applications |

When selecting a plastic sheet extruder, understanding the types available is crucial. There are several types of extruders in the market. The most common ones include single-screw, twin-screw, and sheet extrusion systems. Single-screw extruders are typically used for basic applications. They excel at processing standard resins. Twin-screw extruders offer versatility. They are suitable for mixing and compounding. Sheet extrusion systems are specifically designed to produce sheets at a high output.

A report by Statista indicates that the global plastic extruder market is expected to reach 12.6 billion USD by 2025. This growth highlights the increasing demand for plastic sheets in various industries. Therefore, choosing the right extruder can significantly impact your production efficiency and product quality.

Tips: Consider your production volume. If you require high output, a twin-screw extruder may be beneficial. Evaluate the materials you’ll be using. Some extruders work better with specific plastics. Lastly, reflect on space. Larger machines need more room and require proper installation. Investing time in these aspects will minimize future complications.

When selecting a plastic sheet extruder, material compatibility is crucial. Different materials behave differently during the extrusion process. For instance, some plastics require higher temperatures for optimal flow. Others may degrade under excessive heat. Understanding these nuances is essential to avoid production hiccups.

Consider the types of plastics you plan to use. Will you be working with PVC, PET, or polycarbonate? Each material has distinct characteristics. PVC is versatile but can emit harmful fumes when overheated. PET, on the other hand, is recyclable and more environmentally friendly. Yet, improper handling can lead to quality issues.

Trial runs can be enlightening. Experimenting with small batches helps identify any potential setbacks. You might find that your chosen extruder struggles with certain materials. Document your findings thoroughly. This reflection helps refine your approach and ultimately leads to better production outcomes. The best equipment is only part of the solution; matching it with the right materials is where success lies.

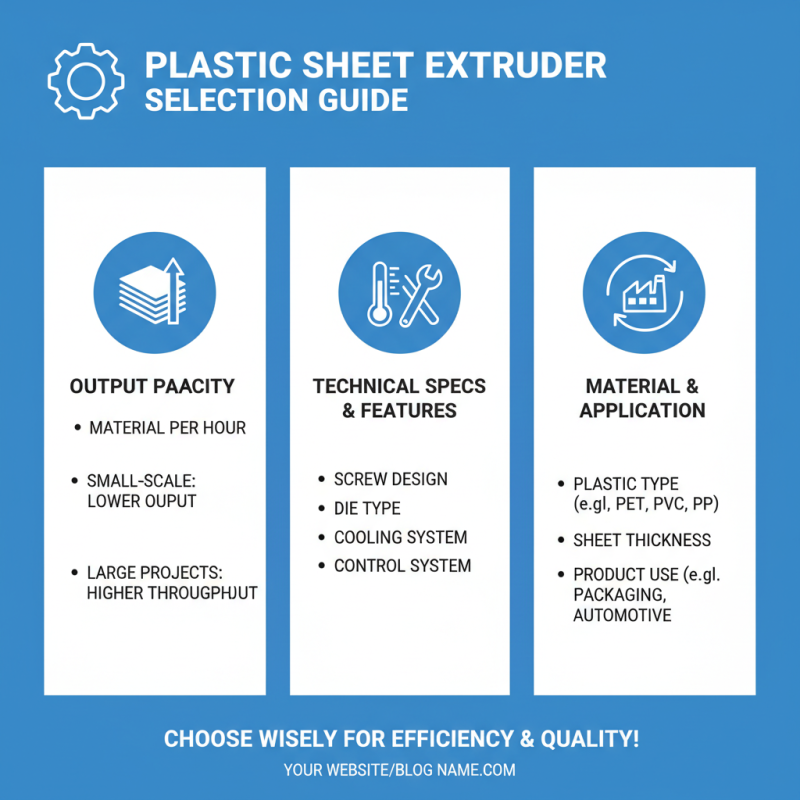

Choosing the right plastic sheet extruder depends heavily on its technical specifications and features. You should consider the machine's output capacity, which indicates how much material it can process per hour. For small-scale operations, a lower output may suffice. However, larger projects might require higher throughput.

Check the temperature control options. Precise temperature management affects the quality of the final product. Look for models with multiple heating zones. This allows for better consistency during the process. Pay attention to the extrusion width. Wider sheets could mean a bigger investment. Make sure it fits your production needs.

Consider the drive system of the extruder. Options include gear-driven and direct-drive systems. Each has its pros and cons. A gear-driven system might be more robust but can be harder to maintain. Understand the implications of each choice. Don’t ignore the material compatibility. Not all extruders work with every type of plastic. This can limit your production flexibility. Research each specification carefully and reflect on your unique requirements.

When choosing a plastic sheet extruder, budget and operational costs play a crucial role. Extruder prices can vary significantly based on capacity and features. A 2021 industry report showed that small to medium-sized extruders range from $25,000 to $100,000. This variance can impact your financial planning. While higher-end models often promise better efficiency, their return on investment isn’t always guaranteed.

Operational costs are another key factor. Energy consumption can account for up to 30% of overall production costs. A more efficient extruder may cost more but can lead to savings over time. According to industry data, machines with lower energy usage can reduce costs by approximately $10,000 annually. Some manufacturers might overlook maintenance costs in their calculations. Neglecting this can lead to unexpected expenses.

Additionally, consider labor costs. More advanced machines often require skilled operators, which can increase payroll. A surprising number of companies underestimate the importance of training. Inadequate training could result in lower production efficiency or safety issues. Balancing these factors is essential for making a well-informed decision.