Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

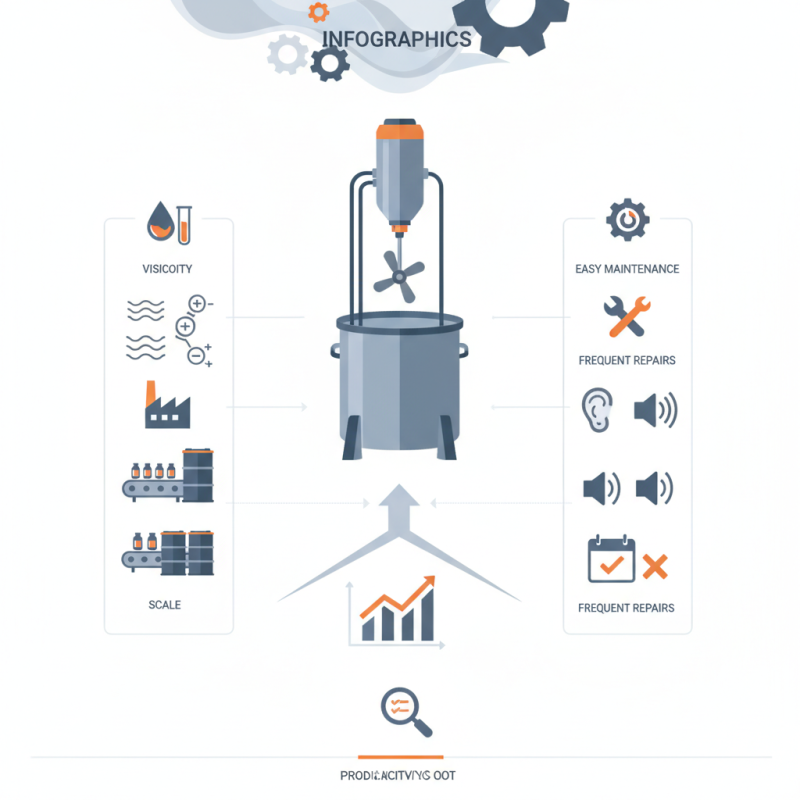

Choosing the right pneumatic mixer for your industrial needs is crucial. A pneumatic mixer can enhance efficiency and productivity. However, making the right choice can be challenging.

There are several factors to consider. First, assess the materials you will mix. The viscosity and chemical properties matter. Then, think about the size and scale of your operations. A small production line may not need a heavy-duty mixer. Additionally, noise levels should not be ignored. Some mixers can be quite loud.

It’s important to consider maintenance too. A mixer requiring constant repairs will slow down operations. Reflect on all these factors carefully. Finding the perfect pneumatic mixer might take time, but it’s worth the effort for long-term gains.

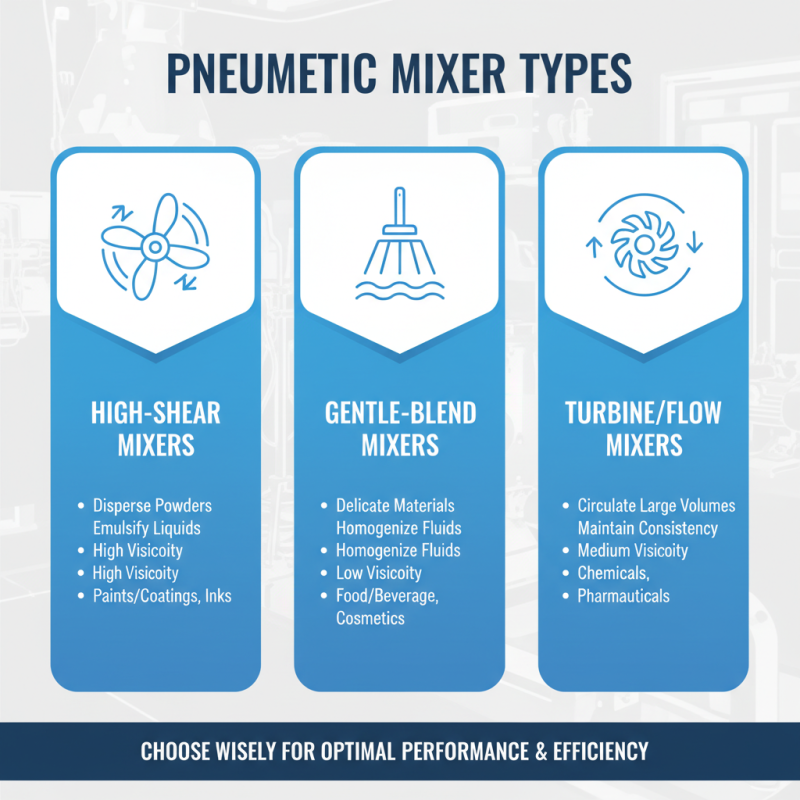

When selecting a pneumatic mixer, understanding the various types available is crucial. There are several designs suited for different industrial applications. Some mixers create a high-shear effect, ideal for dispersing powders into liquids. Others focus on gentle mixing, perfect for blending delicate materials. Choosing the right type can affect effectiveness and efficiency.

Bowl mixers play a significant role in industries requiring thorough mixing. They combine materials in a circular motion. Their capacity can usually accommodate large batches. Another type, the batch mixer, offers flexibility for smaller quantities. However, batch mixers may lead to inconsistent results if not monitored carefully.

Ultimately, the choice should align with specific production needs. Mixing times and product characteristics must be considered. Not every mixer handles every task equally well. Balancing performance and reliability while staying within budget presents challenges. Regular evaluation of mixer performance is necessary for improvement.

When choosing a pneumatic mixer for industrial applications, several key factors should be evaluated carefully. The first is the viscosity of the materials you will be mixing. Thicker substances require robust mixing action. If you overlook this, you may end up with an ineffective mix. The size and capacity of the mixer also play critical roles. A mixer too small may not meet production demands.

Efficiency is another essential aspect. Consider energy consumption and maintenance requirements. An inefficient mixer can lead to higher operational costs over time. Pay attention to the available mixing technology. Some designs are better for certain materials. This might confuse some buyers. A well-structured process for selection will save time and resources in the long run.

Finally, don't forget about the compatibility with existing systems. This is often underestimated. A mixer that works well on paper might not fit smoothly into your workflow. Sometimes, trial and error reveals the best option. Always be open to adjustments. Each application may have unique challenges. Taking these factors into account will help you choose the right pneumatic mixer for your needs.

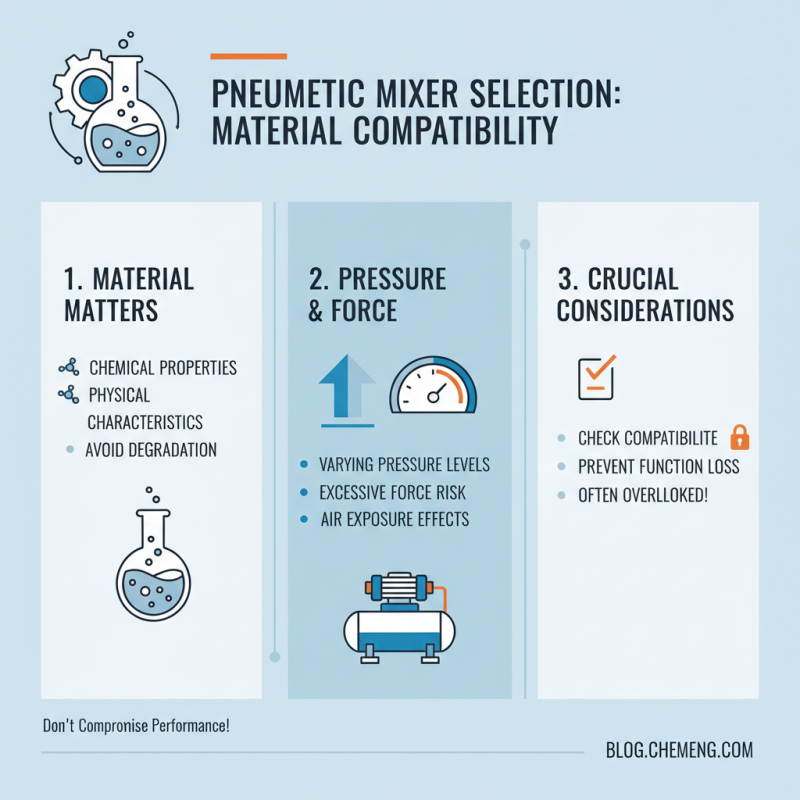

When selecting a pneumatic mixer, material compatibility is crucial. Different materials react differently under varying pressure levels. It's important to consider the chemical properties and physical characteristics of the materials to be mixed. Some materials may degrade or lose functionality when exposed to air or excessive force. This is often overlooked.

For example, some delicate substances require gentler handling. They can easily break down or change chemical properties. Using a pneumatic mixer designed for more robust materials might not yield desired results. You could end up with a non-homogeneous mix. This could waste time and resources. Assessing the specific needs of each material is essential.

Moreover, mixing efficiency can be impacted by material characteristics. Viscosity and density matter. Thicker materials may need a different approach than lighter ones. Ignoring these factors can lead to poor performance. Sometimes, you might need to test different mixers to find the right fit. The right balance ensures optimal results and meets production goals. Respecting material compatibility can reduce errors and improve outcomes.

Pneumatic mixers are essential for many industrial processes. However, they require proper maintenance to ensure optimal performance. According to industry reports, about 30% of mix-related downtime is due to maintenance issues. Regular checks of components can greatly reduce this. Keep an eye on air filters, hoses, and seals.

Proper lubrication is critical. It helps prevent wear and tear on moving parts. A well-lubricated mixer operates more efficiently. Remember, using the right lubricant is key. Avoid over-lubricating, as it can attract dust and dirt. This leads to further issues down the line.

Tips: Schedule monthly inspections to maintain peak performance. Document all maintenance activities to track patterns. If performance dips, it may signal underlying issues needing attention. Regular attention to pneumatic mixers keeps operations running smoothly.

This bar chart illustrates key features of pneumatic mixers relevant to industrial needs. The data includes mixing speed, power consumption, weight, volume, and price, providing an overview for selecting the right mixer for maintenance and operational considerations.

Choosing the right pneumatic mixer involves a careful balance between cost and performance. High-performance mixers often come with a higher price tag. However, they may save money in the long run through increased efficiency and durability. Understanding your specific needs is crucial in this decision-making process.

When evaluating mixers, consider the materials you will be mixing. Some materials require more power and specialized mixers. A less powerful mixer might save initial costs, but could lead to inefficiencies. This can impact both product quality and production time, resulting in increased costs later.

Tips: Assess your mixing volume and viscosity requirements. Determine the ideal mixing speed needed for your applications. This will guide you toward suitable models without overspending. Remember, the cheapest option may not always be the best. A powerful, efficient mixer could be a wise investment for your operations.