Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

Choosing the right Extruder Screw is crucial for optimal processing in various industries. Reports indicate that the correct screw design can improve output by 30%. A well-selected screw enhances material flow and mixing efficiency. It should align with the application’s requirements.

Different materials require specific screw geometries. For example, polymers need a different approach than food products. It's essential to consider aspects like shear rate and temperature. Neglecting these parameters can lead to production inefficiencies.

However, many companies face challenges in making the right choice. Some rely on generic solutions, which may not fulfill their needs. This oversight can result in wasted resources and time. Reflecting on screw selection is important. The impact on product quality can’t be overstated. A thoughtful approach ensures better performance and consistency in production.

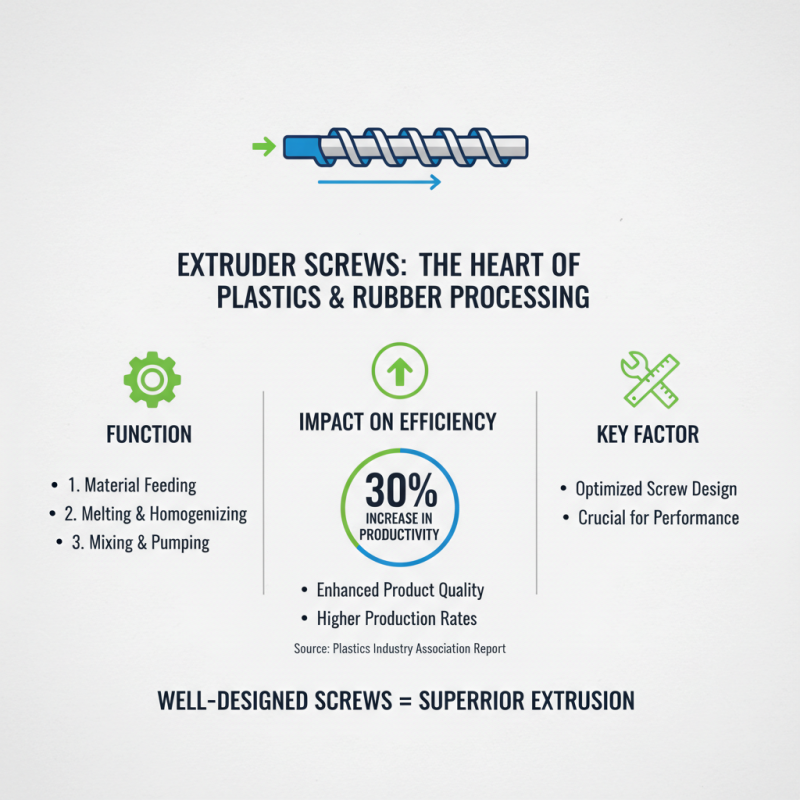

Extruder screws are fundamental components in the plastic and rubber processing industries. They play a crucial role in material feeding, melting, and mixing. A well-designed screw can significantly enhance the efficiency of an extruder, affecting product quality and production rates. According to a report from the Plastics Industry Association, the right screw design can improve productivity by up to 30%.

Understanding the basic functions of extruder screws is crucial. The flight design, diameter, and length all influence how materials are processed. A larger diameter can increase throughput but may reduce the quality of mixing. Reports indicate that improper screw selection can lead to material degradation, impacting the final product. There’s often a trade-off between speed and quality that needs careful consideration.

Many users fail to account for the nuances in their applications. Some may choose a standard screw, overlooking specific requirements, like shear rate and material characteristics. This can lead to inconsistent results or equipment wear. Manufacturers often recommend testing different screw configurations to evaluate performance. However, choosing the right screw is rarely straightforward. It's something that requires ongoing evaluation and adjustment.

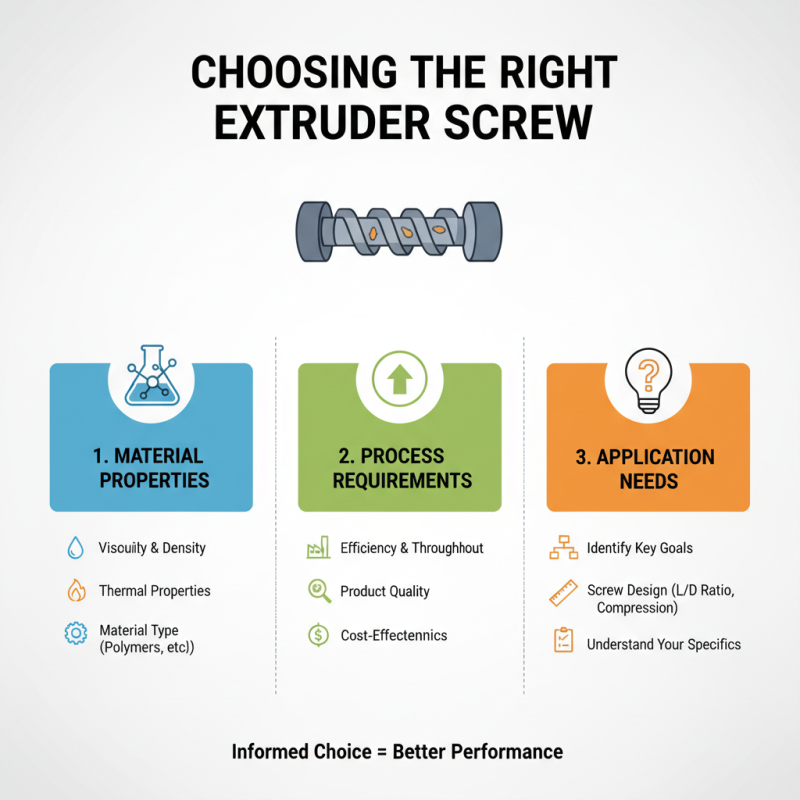

Choosing the right extruder screw is crucial for your application. It impacts efficiency, product quality, and cost. Start by identifying key requirements of your process. What materials will you be processing? The viscosity, density, and thermal properties matter. Understand your specific needs before making a decision.

Tips: Analyze the material characteristics. This will guide your screw design. For instance, a high-viscosity material may require a different screw profile than a low-viscosity one. Don't forget about the needed output rate. This can influence the length and diameter of the screw.

Consider how long the screw will be running in production. Screws wear out over time. Reflect on how maintenance and replacement will affect your operation. Sometimes, compromises must be made between performance and longevity. A screw that excels in one area may fall short in another. It’s key to weigh these factors carefully before finalizing your choice.

Choosing the right extruder screw is crucial for achieving optimal performance in your processing application. Various types of extruder screws exist, each designed for specific materials and processes. Single-screw extruders are versatile and widely used. They excel with low-viscosity materials but may struggle with high-viscosity applications. A recent industry report indicated that around 30% of extrusion failures stem from inadequate screw selection.

On the other hand, twin-screw extruders offer better mixing and compounding capabilities. They are ideal for processing heterogeneous materials, providing uniform distribution. Data suggests that twin-screw systems can increase output by up to 40% when handling complex formulations. However, they may require more sophisticated control systems, which could complicate setup. Often, users underestimate these complexities, leading to operational inefficiencies.

When choosing an extruder screw, consider factors such as material viscosity and desired output rate. It’s not always simple. Many processors overlook how material properties influence screw design. A mismatched screw can cause power surges and inconsistent melt quality. In some cases, it may take trial and error to find the perfect screw configuration. Understanding the limitations and capabilities of different screw designs can significantly enhance process efficiency.

Choosing the right extruder screw is crucial for optimal processing. When evaluating material compatibility, consider the properties of the polymers you plan to use. Different materials, such as thermoplastics and thermosets, behave uniquely. Their flow rates and viscosity can significantly impact extrusion performance.

Processing conditions also play a vital role. Temperature control is key; high temperatures may degrade sensitive materials. Pressure settings should match the material's requirements to avoid defects. If the screw design doesn't align with these factors, issues will arise.

Some challenges may not be apparent at first glance. For instance, poor material flow can lead to uneven products. It's essential to test various screws and settings. This iterative process may seem tedious, but it helps refine your approach. Understanding the nuances of materials and conditions is a journey worth undertaking.

Choosing the right extruder screw can significantly impact the efficiency of your operation. A common mistake is not considering the material being processed. Each material requires a specific screw design for optimal performance. If you use a standard screw for a complex polymer, you may encounter issues. Think about the viscosity and flow rate.

Another error is ignoring the screw length-to-diameter (L/D) ratio. Many assume a longer screw equals better mixing. However, this isn't always true. Sometimes, a shorter screw can work better for certain applications. It’s essential to assess whether your application truly demands a longer design. Don't overlook this detail.

Finally, many fail to incorporate temperature control into their selection. The operating temperature affects the screw's performance and lifespan. A screw that works well at one temperature might underperform at another. Consider how temperature variances will affect your specific setup. Reflection on these aspects is crucial for a successful extruder screw selection.