Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In the construction industry, efficiency is key. Portable crushers have become essential tools for many projects. According to a report by Global Market Insights, the portable crusher market is projected to reach $1.5 billion by 2026, driven by rising construction activities worldwide. The ability to crush materials on-site offers significant cost savings and minimizes transportation needs.

Expert John Smith, a leading figure in the portable crushing sector, emphasizes, “A portable crusher saves time and enhances productivity.” His insight highlights the importance of these machines in modern construction. However, not all portable crushers are created equal. Companies must evaluate their needs carefully.

While portable crushers provide many benefits, issues can arise. For instance, improper operation may lead to equipment damage. Additionally, selecting the wrong model may affect efficiency. Understanding the specific qualities and limitations of portable crushers is crucial for success in construction projects.

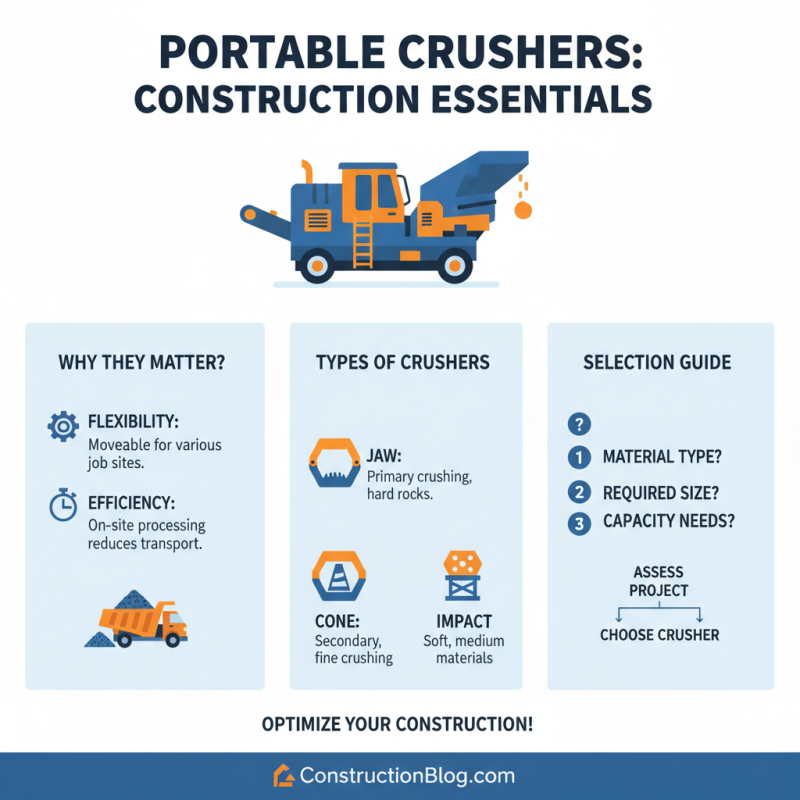

Portable crushers play a crucial role in modern construction projects. They offer flexibility and efficiency. With their compact design, they can be easily transported to various job sites. This mobility saves time and reduces transportation costs. Projects can proceed without delays, which is vital in competitive markets.

In many cases, using a portable crusher can lead to significant waste reduction. Instead of hauling materials away, concrete and asphalt can be recycled on-site. This process minimizes environmental impact and promotes sustainability. However, not all portable crushers are equal. Some may not handle certain materials well. Hence, careful consideration is necessary when selecting equipment.

The importance of portable crushers also lies in their ability to adapt to changing project needs. They can quickly switch from crushing concrete to processing gravel. Yet, this versatility can lead to confusion. Operators might struggle with varying settings and maintenance. Investing in training can mitigate these issues. Effective use of portable crushers ultimately enhances construction efficiency and contributes to a more streamlined process.

Portable crushers are essential for construction projects. They offer flexibility and efficiency on job sites. Various types cater to specific needs, but selecting the right one can be difficult.

Jaw crushers are popular for their ability to crush hard materials, like granite. According to industry data, they can achieve a reduction ratio of about 6:1. This effectiveness helps in recycling concrete and other materials. However, they require enough clearance and may not be suitable for confined spaces.

Impact crushers offer another option. These are ideal for softer materials like limestone and asphalt. They are efficient, yielding high production rates. Industry reports show that they can produce up to 500 tons per hour. But, they may face challenges with harder materials. Users often find that understanding the material type is crucial. Sometimes, operators struggle with maintenance, especially in remote areas. Each type of crusher has its pros and cons, requiring careful consideration for optimal project outcomes.

Choosing the right portable crusher for your construction projects can be a challenge. You need to consider several key features. Mobility is crucial. A lightweight and compact model will make transportation easier. Look for crushers with robust frames that can withstand rough handling.

Another important feature is the crushing capacity. Select a machine that aligns with the scale of your projects. A higher capacity will reduce processing time, but it might be too much for small tasks. Think about the materials you will be working with as well. Some crushers handle concrete better, while others are suited for softer materials.

Don't overlook power options. Different machines have various power sources. Some are fuel-operated, while others run on electricity. Evaluate your site’s capabilities before making a decision. Also, pay attention to maintenance requirements. A complex machine may increase downtime for repairs. Finding the right balance between power and ease of maintenance is key.

Portable crushers are increasingly essential in modern construction. Reports indicate that over 80% of contractors prefer portable options due to their versatility and efficiency. These machines can crush various materials on-site, reducing the need for transporting heavy loads. They are effective for gravel, concrete, and asphalt, making them a valuable asset for diverse projects.

When evaluating portable crushers, factors such as weight, power, and mobility come into play. A study shows that models weighing under 10,000 pounds achieve a balance between productivity and ease of transport. Many users report challenges in maneuvering larger models in tight urban job sites. Additionally, maintenance can be an issue; improper care leads to shortened lifespans and costly repairs.

The leading brands typically offer an array of features. Some standout with hydraulic systems for easier adjustment, while others emphasize highly efficient crushing processes. However, some users express concerns about the learning curve required to operate these advanced machines. It’s crucial to weigh the pros and cons carefully before making a purchase.

Operating and maintaining portable crushers require attention to detail. Regular inspections are crucial. Operators should monitor wear patterns and adjust settings accordingly. Data from industry reports show that improper maintenance can lead to a 25% decrease in efficiency. Small issues, if neglected, may escalate quickly.

Dust control is another vital aspect. A study indicated that up to 30% of operational downtime is linked to dust management failures. Portable crushers can generate significant dust during operation. Therefore, using water or other dust suppressants can greatly reduce health risks and equipment wear.

Training personnel is equally important. Misunderstanding of the equipment can lead to costly mistakes. Workers need to be aware of hazards and safe operation protocols. Educational programs have been shown to improve safety and production by 15%. Continuous learning should be encouraged. Each project is unique, and adaptability is key.