Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

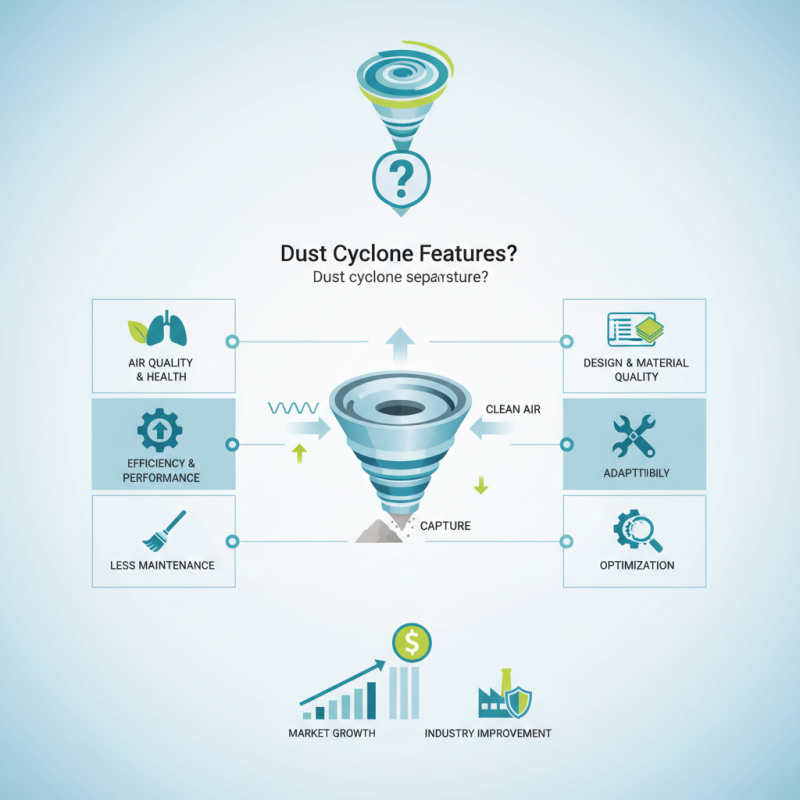

The dust cyclone industry has seen significant advancements in recent years. It is estimated that market growth will reach $1.2 billion by 2025. This growth is fueled by increasing awareness of air quality and environmental health. "Dust Cyclones are crucial for improving indoor air quality," says Dr. John T. Miller, a leading expert in dust control technologies. His insights highlight the importance of efficient dust collection systems.

Dust cyclones offer various features that enhance performance and efficiency. Their ability to separate and capture dust particles effectively sets them apart from traditional filters. For instance, with higher airflows, they can maintain a cleaner environment with less maintenance. The effectiveness of a dust cyclone largely depends on its design and material quality. Yet, not all dust cyclones work equally well under different conditions.

Despite advancements, challenges remain in maximizing efficiency across all applications. Users often experience varying levels of performance based on their setup. Optimizing a dust cyclone for specific needs is key. Understanding these features can lead to better decisions that ultimately improve dust management in various industries.

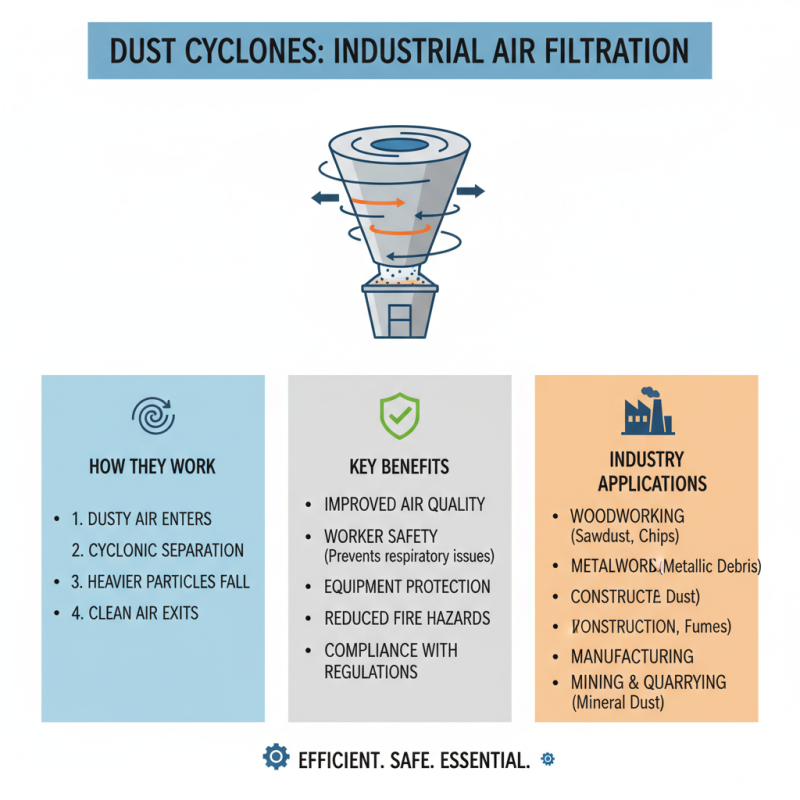

Dust cyclone systems play a crucial role in air filtration and dust extraction. They are widely used in various industries, including woodworking, metalworking, and manufacturing. These systems primarily consist of several key components that ensure efficient dust collection. A cyclone separator is at the heart of the system. It uses centrifugal force to separate dust particles from the air, with an efficiency rate often exceeding 99% for larger particles.

The collection bin is another essential component. It captures the separated dust for easy disposal. This bin should be designed for easy access and handling. A proper filtration system is also vital. Filters capture finer particles that the cyclone might miss. According to industry reports, up to 30% of airborne dust consists of particles smaller than 10 micrometers, making quality filtration critical.

However, not all systems perform equally. Design flaws can reduce efficiency. For example, a poorly designed inlet can disturb airflow, leading to dust re-entrainment. Regular maintenance is also essential for optimal performance. Clogged filters can degrade air quality and affect system efficiency. Despite the technology's advancements, there is always room for improvement. Monitoring airflow and particle size is crucial for ongoing optimization.

Cyclone separators are vital in dust collection systems. Their efficiency often determines the overall effectiveness of air quality control in various industries. According to a recent industry report, cyclone separators can achieve up to 99% particle removal efficiency at optimal conditions. This means they can significantly reduce airborne dust particles, contributing to healthier work environments.

However, efficiency is influenced by several factors. The design of the cyclone, airflow rates, and particle size all play crucial roles. For instance, larger particles are easier to remove, while finer particles often escape capture. A study highlighted that particles below 10 microns can be particularly challenging to filter out. This raises concerns about the long-term efficiency of cyclone separators when faced with changing operational conditions.

Yet, even the best systems can have flaws. Regular maintenance is necessary to ensure that cyclones operate at peak efficiency. Build-up of dust may reduce airflow and efficiency over time. Furthermore, the choice of cyclone design can impact performance metrics. Simple modifications can lead to better particle separation, but these changes may also require careful analysis to avoid unintended consequences. Balancing efficiency and practicality remains a challenge in optimizing cyclone performance.

Dust cyclones are essential tools in many industrial settings. They efficiently separate dust and debris from the air, improving air quality. With better air quality, workers can breathe easier. This leads to fewer health issues, which ultimately benefits productivity.

Using dust cyclones also means cleaner equipment. Machines operate better without dust accumulation. Regular maintenance becomes less frequent. However, not all dust cyclones are created equal. Some may struggle with larger particles, and that can lead to issues. Finding the right cyclone for specific needs is crucial.

Moreover, dust cyclones can reduce waste. They allow for the collection of reusable materials. This helps in minimizing operational costs. Still, it’s important to monitor system efficiency regularly. Failure to do so might result in reduced performance. In industrial environments, small details matter a lot. They can make or break the efficiency of an operation.

To maintain optimal dust cyclone performance, regular maintenance is crucial. According to a report by the National Institute of Standards and Technology (NIST), poorly maintained dust collection systems can lose up to 30% of their efficiency. This inefficiency can lead to increased operational costs and lower air quality. Cleaning the filter regularly is one of the simplest and most effective ways to ensure uninterrupted airflow and suction power.

Another important aspect of maintenance is checking for leaks and blockages. Leaks in the ductwork can waste energy and reduce vacuum efficiency. A study by the American Society of Mechanical Engineers found that even small leaks can significantly decrease overall performance. Regularly inspecting the system can help identify these issues early. Additionally, operators should pay attention to the cyclone's component wear over time. It is often overlooked but can lead to significant performance degradation if not addressed.

Dust cyclones require a proactive approach to maintenance. Neglecting this can result in more frequent breakdowns. Regular performance evaluations should take place every few months. This not only saves costs in the long run but also extends the lifespan of the equipment. Keeping track of maintenance schedules can be cumbersome, yet it pays off in efficiency and cleaner work environments.

Dust cyclones play a crucial role in various industries. Their efficiency in removing fine particles makes them popular in manufacturing and construction. In woodworking, dust cyclones collect wood chips and sawdust, maintaining a clean workspace. This prevents respiratory issues among workers. In metalworking, they capture metallic debris, reducing hazards.

Tips: Regular maintenance is key. Check for clogs often. A clean cyclone functions better. Monitor the air flow to ensure efficiency.

In the food industry, dust cyclones help in processing grains and powders. They keep the environment clean. However, sometimes they may struggle with sticky substances. It's essential to choose the right cyclone type for specific materials.

Tips: Test materials before installation. Understand their properties for a tailored solution. Ineffective setups can lead to operational challenges.