Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

Screw conveyors are an essential component in the landscape of material handling systems, renowned for their versatility and efficiency. These innovative devices utilize helical screws to transport bulk materials through a confined space, making them ideal for a wide range of applications across various industries. The design of screw conveyors not only ensures a consistent material flow but also allows for easy adjustment to meet specific operational demands.

The benefits of using screw conveyors extend far beyond mere transportation; they contribute significantly to process efficiency and productivity. By employing screw conveyors, businesses can minimize waste, reduce labor costs, and maintain a safer working environment. Additionally, their robust construction and ability to handle various materials—from powders to granules—make them a preferred choice for operations seeking reliability and ease of maintenance. This article will delve into the top 10 benefits of using screw conveyors, highlighting why they are an indispensable asset for efficient material handling.

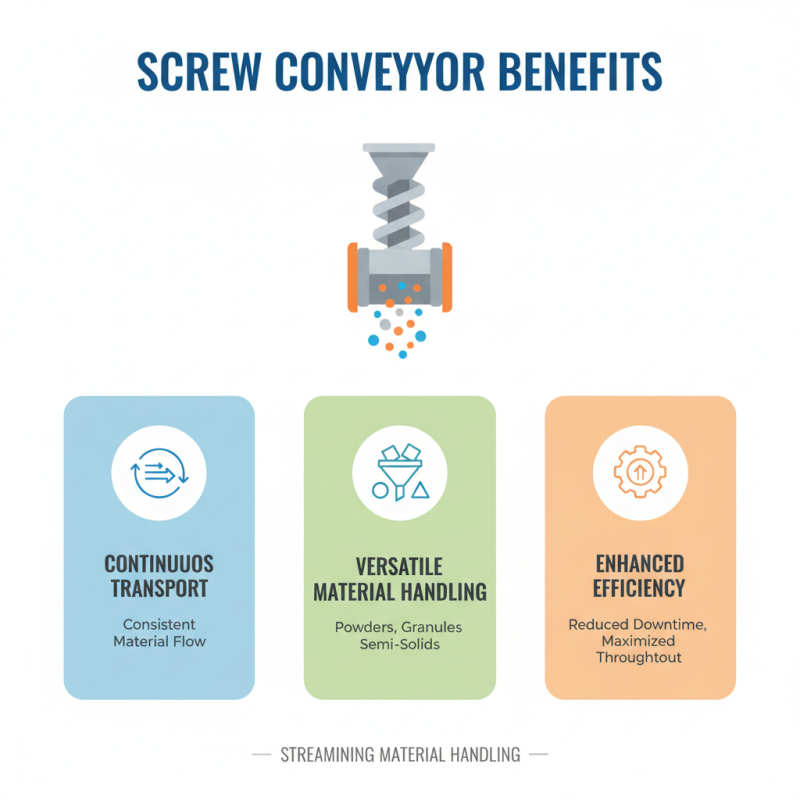

Screw conveyors are a pivotal component in the realm of material handling, offering numerous advantages that significantly enhance operational efficiency. One of the primary benefits is their ability to transport materials in a continuous and consistent manner. Unlike traditional belt conveyors, screw conveyors can handle bulk materials in various states, including powders, granules, and semi-solid mixtures. This versatility allows industries to streamline their processes, minimizing downtime and maximizing throughput.

In addition to their adaptability, screw conveyors are designed for space efficiency. Their compact nature enables them to fit into tight spaces, making them suitable for facilities where space is a premium. This design not only saves valuable floor space but also allows for the installation of conveyors at various angles, optimizing the routing of material movement. Moreover, the enclosed construction of screw conveyors minimizes dust emissions and minimizes material spillage, contributing to a cleaner work environment and reducing material loss. Overall, these features underscore the importance of screw conveyors in enhancing material handling efficiency across various applications.

Screw conveyors are an excellent choice for efficient material handling, particularly due to their ability to minimize material damage. One of the primary advantages of a screw conveyor is its gentle handling capabilities. Unlike traditional conveying methods that may involve abrupt accelerations or impacts, screw conveyors provide a continuous and controlled movement of materials. This results in less stress on the conveyed materials, protecting them from degradation and preserving their integrity throughout the handling process.

Moreover, the design of screw conveyors aids in reducing friction and impact during transportation. The helical screw design allows for a smooth flow, which is critical for fragile materials such as powders, grains, or other aggregates that can easily be damaged. By adjusting the speed and angle of the conveyor, operators can further customize the handling process to suit the specific characteristics of the materials being transported, ensuring that even the most delicate items are handled with care and efficiency. This focus on minimizing material damage not only enhances the quality of the products but also extends their longevity, making screw conveyors a smart investment for manufacturers aiming to optimize their material handling processes.

Screw conveyors have established themselves as vital components across a range of industries due to their remarkable versatility in handling various types of materials. According to the Conveyor Equipment Manufacturers Association, screw conveyors are capable of transporting granular materials, powders, and even small pieces of solid materials, making them ideal for sectors such as agriculture, mining, and food processing. The adaptability of screw conveyors allows them to efficiently manage different material characteristics, including density and moisture content, ensuring operational efficiency.

In addition to their flexibility, screw conveyors can be configured in various layouts, whether horizontal, inclined, or vertical. This adaptability is essential for accommodating limited space in production facilities without compromising on productivity. Reports indicate that industries that incorporate screw conveyors often report reduced operational costs and improved workflow efficiency. For instance, a study by the American Society of Mechanical Engineers revealed that businesses utilizing these systems noted a 15% increase in material handling efficiency.

Tips: When selecting a screw conveyor, consider the material's properties and the desired capacity to ensure optimal performance. It's also wise to conduct thorough maintenance checks periodically to prevent downtime, which can significantly affect productivity levels. Additionally, outfitting your screw conveyor system with advanced sensors can provide real-time data, further enhancing operational effectiveness.

Screw conveyors are increasingly recognized for their space-saving designs, making them a smart choice for industries that require efficient material handling solutions. Unlike traditional conveyor systems, screw conveyors utilize a compact configuration, allowing them to fit into tight spaces while still providing effective transport of bulk materials. This design not only optimizes the use of available space but also reduces the overall footprint of the handling system, which is especially beneficial in facilities with limited room for equipment installation.

In addition to their compact design, screw conveyors offer remarkable installation flexibility. They can be configured to operate at various angles and can be adapted to fit different layouts within a facility. This versatility enables them to be used in a variety of applications, from horizontal to inclined transport. Furthermore, the modular design of screw conveyors allows for easy adjustments or expansions in existing systems, accommodating changing production demands without extensive overhauls or structural changes. This adaptability ensures that businesses can maintain efficient operations while adjusting to fluctuating material handling needs.

Screw conveyors play a crucial role in modern material handling systems, significantly contributing to enhanced automation within various industries. By automating the transportation of bulk materials, these conveyors minimize the need for manual labor, allowing businesses to redirect their workforce to more strategic tasks. This transition not only improves productivity but also reduces the risk of workplace injuries associated with manual material handling. With advanced technology, screw conveyors can seamlessly integrate into existing production lines, streamlining processes and ensuring consistent material flow.

Moreover, the reduction in labor costs is one of the standout benefits of using screw conveyors. By decreasing the dependency on manual intervention, companies can save on labor expenses and training costs, while also benefiting from increased operational efficiency. Automation leads to more reliable and predictable material handling, which is essential for maintaining tight production schedules. As organizations strive for leaner operations, the adoption of screw conveyors offers a compelling solution that aligns with the goals of reducing overhead and enhancing overall performance. This efficient handling method not only optimizes resource allocation but also provides a sustainable approach to meet growing demands in various sectors.

| Benefit | Description | Impact on Operations |

|---|---|---|

| Increased Efficiency | Screw conveyors transport materials quickly and continuously. | Reduces downtime and boosts overall productivity. |

| Space Saving | They can be installed in tight spaces, utilizing vertical and horizontal movement. | Minimizes the footprint of material handling systems. |

| Reduced Labor Costs | Automation leads to less manual handling of materials. | Lowers workforce costs and improves safety. |

| Versatility | Effective for various materials - wet, dry, and granular. | Applicable in multiple industries like agriculture and manufacturing. |

| Minimal Maintenance | Simple design leads to less wear and tear. | Reduces maintenance costs and machine downtime. |

| Shielding from Contaminants | Closed design protects materials from environmental factors. | Improves product quality and reduces waste. |

| Easy Installation | Can be fitted into existing infrastructure with minimal hassle. | Facilitates quick setup and modifications. |

| Controlled Material Flow | Allows for precise control over the transport of materials. | Enhances process consistency and reduces errors. |

| Safety Features | Designed with safety and efficiency in mind. | Reduces accidents related to manual labor. |

| Cost-Effectiveness | Initial investment is offset by long-term savings. | Provides a good return on investment. |