Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

In the rapidly evolving field of industrial technology, Vertical Shaft Impact (VSI) systems stand at the forefront. Industry expert Dr. Emily Carter emphasizes, "Innovation in VSI technology is crucial for optimizing efficiency and sustainability." As we approach 2026, we witness a surge of advancements designed to enhance VSI systems. These innovations promise improved energy efficiency and higher material processing capabilities.

The integration of artificial intelligence is reshaping how VSI systems operate. For instance, smart sensors can now monitor performance in real-time, ensuring optimal operation. However, challenges remain. Not all companies adopt these technologies effectively. Some remain stuck in outdated practices, missing opportunities for growth.

Moreover, sustainability is a key focus. Many companies are exploring eco-friendly materials in VSI manufacturing. Yet, meaningful change often encounters resistance. There is a growing need for industry-wide collaboration. By sharing successes and failures, the sector can advance as a whole. Vertical Shaft Impact technologies are at a pivotal point, urging stakeholders to reflect and innovate continually.

In recent years, vertical shaft impact technology has seen remarkable advancements. These innovations focus on efficiency and versatility. Many machines are designed to optimize material processing for various industries. They efficiently crush and shape materials, such as aggregates, for construction purposes. The improved design of rotor systems allows for better particle acceleration. This change enhances the quality of the final product.

Yet, challenges remain. While many innovations boost productivity, some machines lack adaptability. A one-size-fits-all solution rarely works in different operational settings. Some operators struggle to fine-tune these machines for specific materials. Over time, wear and tear also leave impact machines needing maintenance. This can interrupt production and increase costs unexpectedly.

Additionally, energy consumption is an ongoing debate in vertical shaft impact technology. Some newer models claim reduced energy usage, but real-world data varies. It raises questions about whether these technologies live up to their promises. Ultimately, while progress is evident, the industry must remain critical. There is room for improvement in resilience and efficiency across different applications.

As we look toward 2026, vertical shaft impact (VSI) technologies continue to evolve. Innovations focus on enhancing efficiency and material processing. Recent studies show that VSI crushers can increase production rates by 25% when utilizing advanced rotor designs. This is crucial for industries requiring high-quality aggregates.

Newer models are integrating smart technology. Features like predictive analytics can monitor performance in real-time. This enables rapid adjustments during operation. Some reports indicate that implementing predictive maintenance can reduce downtime by up to 40%. Such advancements ensure that equipment runs more efficiently, saving costs long-term.

Tips: When selecting VSI technology, consider the materials you'll be working with. Check for compatibility with your processing needs. Also, take time to reflect on potential scalability as your operation grows. Continuous improvements mean staying up-to-date with new features. Embrace the future of vertical shaft impact technologies for better outcomes.

The vertical shaft impact (VSI) technology is evolving rapidly. Many systems are in the market today. Each offers unique features and advantages. A comparative analysis reveals differing efficiencies in material processing and energy consumption.

Some systems excel in producing finer materials. Others prioritize throughput and operational cost. Yet, not all systems live up to their promises. Some can struggle with wear and tear, creating maintenance challenges. It's vital to assess these weaknesses. Users often face the dilemma of choosing between speed and quality.

As innovations develop, flexibility remains crucial. Systems must adapt to varying material types. This includes different sizes and compositions. However, current technologies sometimes fall short. They can be inconsistent in performance across various operational contexts. It’s essential to reflect on these gaps.

The future of VSI technology will likely require a more integrated approach, balancing quality and efficiency.

Vertical shaft impact (VSI) technology is evolving rapidly. Innovations are paving the way for more efficient crushing and shaping processes. The future of this technology lies in automation and artificial intelligence. These advancements enhance precision and reduce operational downtime. New materials are also being tested for better durability and performance under extreme conditions.

Tips for users: Consider how automation can streamline your operations. Explore options that incorporate smart technology.

Another trend is sustainability. Developers are focusing on reducing energy consumption. Eco-friendly materials and practices are becoming standard. Monitoring systems are being integrated to track energy use. This will ultimately lower costs and environmental impact.

Tips for users: Look for technologies that prioritize green practices. Assess your current equipment for energy efficiency. Embrace changes that promote sustainability.

As the industry progresses, adaptation is key. Companies must remain flexible to meet market demands. Reflecting on these changes now may shape long-term success. Staying updated on innovations will ensure competitiveness in the future.

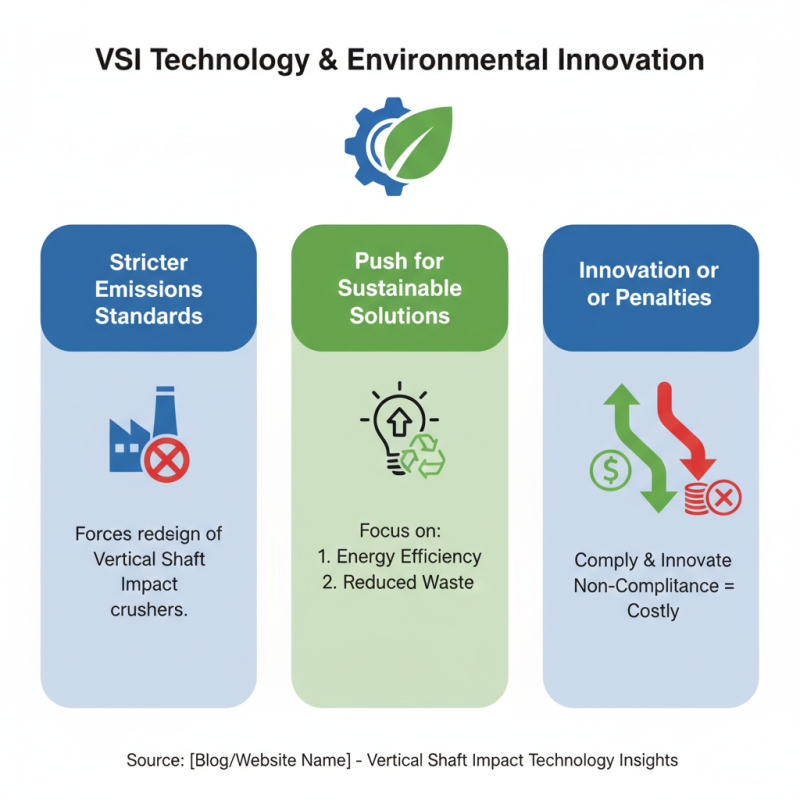

In the rapidly evolving field of vertical shaft impact (VSI) technology, environmental regulations are significantly shaping innovations. Stricter emissions standards push companies to rethink their designs. This pressure can lead to more sustainable solutions, focusing on energy efficiency and reduced waste. Companies must innovate to comply with regulations or risk costly penalties.

However, not all advancements come easily. Some innovations become overly complex. In the rush to meet regulations, essential operational aspects may be overlooked. Companies often struggle to balance environmental goals with practicality. For instance, while new materials can reduce environmental impact, they might complicate the manufacturing process. This creates a need for careful analysis of trade-offs.

Adopting greener technologies can also be financially challenging. The initial costs may deter smaller companies from investing in modern equipment. Yet, sustainable practices often yield long-term savings. Failing to adapt may lead to obsolescence in a highly competitive market. Thus, consistent evaluation and reflection are crucial for future growth.