Leave Your Message

-

Phone

-

Whatsapp

-

E-mail

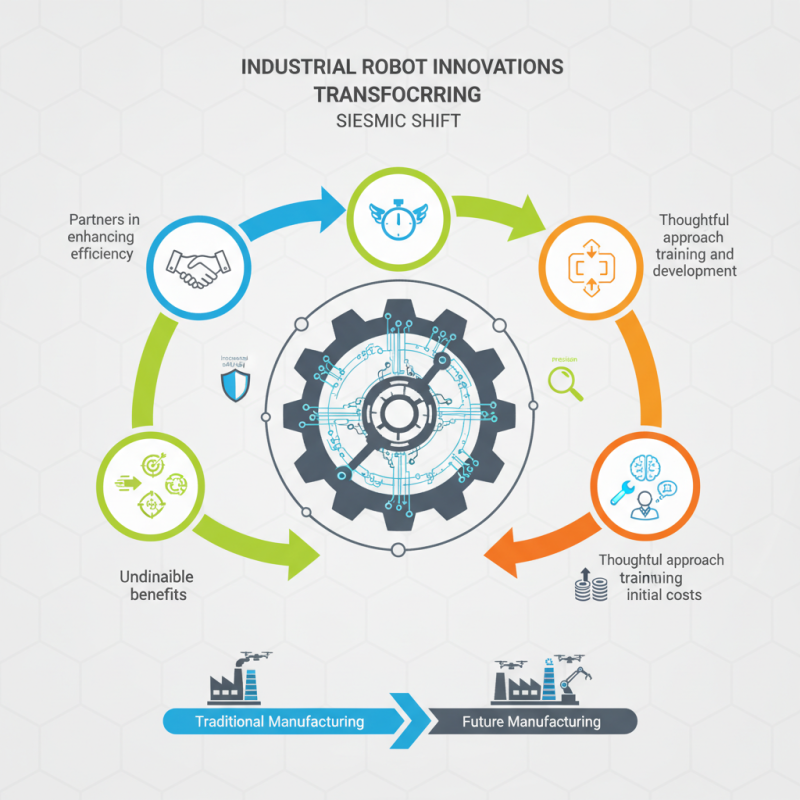

The world of manufacturing is experiencing a seismic shift. The 2026 Best Industrial Robot Innovations are at the forefront of this transformation. Experts believe that these advancements can redefine production processes and enhance productivity. Dr. Emily Chen, a leading figure in the Industrial Robot industry, states, "Embracing innovation is key to staying relevant in manufacturing."

As we explore this evolving landscape, it's clear that Industrial Robots are becoming essential. They are not just machines; they are partners in enhancing efficiency. These robots can work alongside humans, increasing safety and precision. However, industries must carefully consider their implementation. Integrating technology can pose challenges. Companies may struggle with initial costs or workforce resistance.

Yet, the benefits are undeniable. Innovations in Industrial Robots offer speed, accuracy, and flexibility. Industries can customize their operations to meet changing demands. The focus should also be on continuous training and development for staff. To harness the full potential of Industrial Robots, a thoughtful approach is necessary. Ultimately, the future of manufacturing hinges on our ability to embrace these changes.

The industrial robot landscape is evolving rapidly. In 2026, several trends will shape this field. One of the significant innovations is collaborative robots, or cobots. Cobots are designed to work alongside humans safely. In a recent report, it is projected that the cobot market will grow by 30% annually, indicating strong demand.

Data analytics is another key trend. Robots equipped with AI can analyze performance metrics in real-time. This capability allows manufacturers to optimize operations and reduce downtime. Reports suggest that companies using data-driven robots can enhance efficiency by up to 25%. However, this technology is still in its early stages and can be flawed. Misinterpretation of data can lead to operational hiccups.

Tip: Consider investing in training your staff on these new technologies. Adequate training can minimize errors and enhance productivity. Furthermore, evaluate your current processes. Not every existing model may integrate well with new systems.

The rise of autonomous robots is noteworthy as well. These robots can make decisions based on data inputs. However, reliance on autonomy can lead to challenges. Issues related to decision-making accountability might arise. Companies must tread carefully in this uncharted territory.

The manufacturing landscape continues to evolve, driven by key innovations in robotics. These advancements focus on enhancing efficiency and precision.

Collaborative robots, or cobots, work alongside human operators. They help streamline workflows and reduce labor costs. The ability to adapt to various tasks makes them invaluable.

Robots equipped with advanced AI can learn from experience. They analyze production data to optimize processes. This results in fewer errors and improved output quality.

Customization is now easier with flexible robotic solutions. This adaptability allows manufacturers to meet specific client demands swiftly.

Here are some tips for embracing these innovations:

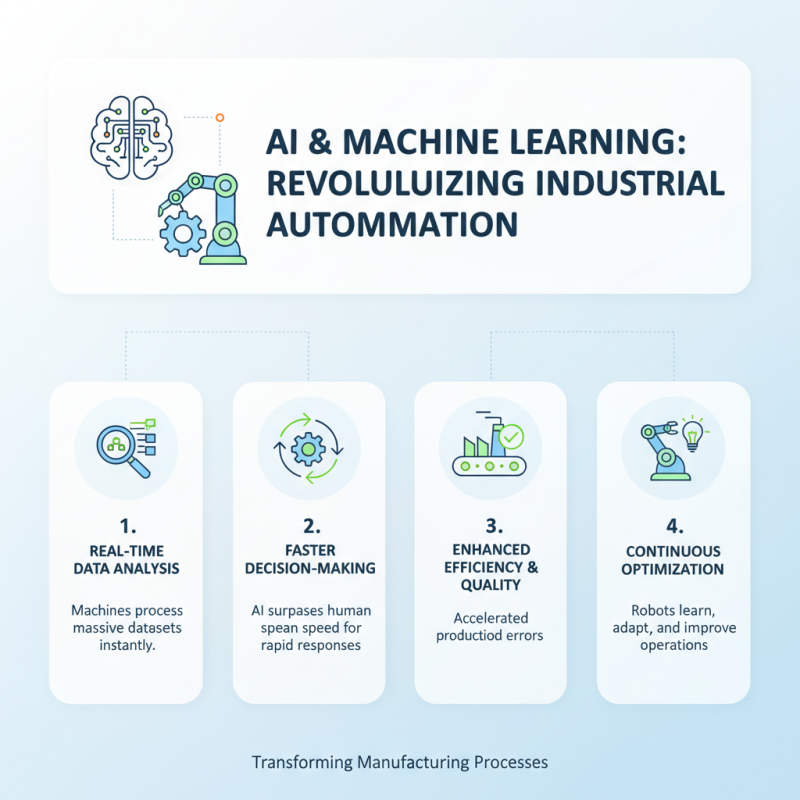

The rise of artificial intelligence (AI) and machine learning is revolutionizing industrial automation. Machines can now analyze vast amounts of data in real time. They make decisions faster than humans ever could. This efficiency transforms manufacturing processes. Automation not only speeds up production but also improves quality. Robots can learn from errors, optimizing their operations continuously.

However, integrating AI isn’t without challenges. There are ethical concerns surrounding job displacement. Workers may fear losing their roles to intelligent machines. Companies must balance technology with the workforce's needs. Training programs can empower employees. This approach helps them adapt and thrive alongside automation.

Moreover, not every AI implementation is flawless. Some systems require extensive tweaking. A malfunctioning AI can disrupt production lines. Companies must remain vigilant. Regular assessments of AI systems are essential for successful integration. Embracing AI is a journey, with both risks and rewards. The future of manufacturing depends on how well we navigate these complexities.

Collaborative robots, or cobots, are changing how we think about manufacturing. Unlike traditional robots, these machines work side by side with humans. This transformation enhances productivity and safety in factories. According to a recent industry report, the global market for collaborative robots is expected to reach $12 billion by 2025. Such growth indicates a strong demand for these innovative solutions.

While numerous benefits exist, challenges remain. Human-robot collaboration can lead to miscommunication. Workers may feel threatened by the presence of robots. A study showed that 30% of employees are hesitant to work closely with robots. Training and adaptation are essential. Factories must invest in programs to ease this transition.

Cobots can perform repetitive tasks. This allows human workers to focus on more complex functions. However, not all tasks suit automation. Identifying which processes to automate requires careful analysis. Companies must weigh costs against potential gains. Balancing efficiency with employee comfort is crucial for a successful implementation.

The rise of eco-friendly innovations in robotics is reshaping manufacturing. According to a report by the International Federation of Robotics, around 40% of companies are investing in sustainable technologies. This shift is aimed at reducing carbon footprints and enhancing energy efficiency. For instance, robots powered by solar energy are gaining traction. They help reduce reliance on traditional power sources and cut operational costs.

While advancements are promising, not all approaches yield positive outcomes. The production of energy-efficient robots can sometimes involve unsustainable materials. Heavy reliance on rare metals raises concerns. A report from the World Economic Forum highlighted that recycling rates for these materials remain low. This creates a paradox in the push for greener manufacturing.

Additionally, the transition to automated systems isn't seamless. Many organizations face challenges in integrating new technologies. The skills gap among workers can slow down implementation. A survey indicated that 75% of manufacturers cite workforce issues as a barrier to adopting advanced robotics. Thus, while the future looks greener, the path to sustainable manufacturing requires careful navigation.